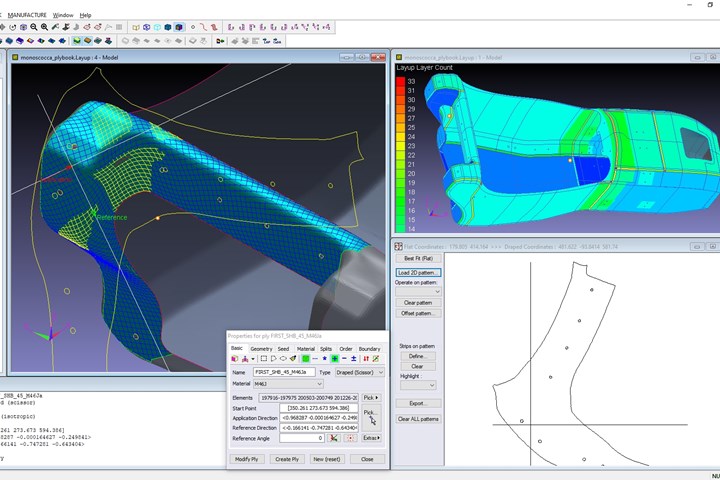

Anaglyph releases Laminate Tools version 4.10

Improvements include new algorithms, added support for Abaqus, Ansys Workbench add-ins and a faster, more reliable SolidWorks add-in.

Source | Anaglyph Ltd.

Composites structural design software specialist Anaglyph Ltd. (London, U.K.) has released version 4.10 of its Laminate Tools software application, delivering user-driven features in the Design, Analysis, Check and Manufacture modules, as well as in the user interface for composites structural design.

Anaglyph notes the considerable effort put in to speed up and enrich important functionalities that can save design time and build a better structural component, such as improving and extending interfaces to third-party partner products in both CAD and FEA domains. The company has also upgraded layup ply imports which now have fast/smart algorithms, supporting edge splits and seeds; added support for Abaqus 2020; the ability to export Abaqus solid mesh based on layup surface; Ansys Workbench add-in implementation; and a faster, more reliable SolidWorks add-in for plies with a large number of surfaces.

Laminate Tools is a stand-alone Windows application that addresses the entire geometry import-design-analysis-check-manufacture process of composites structural design. Used by composite structures designers and stress analysts in automotive, aerospace, marine, energy and leisure industries, it links the various disciplines, communicates original data between all involved in the process and conserves design time. Laminate tools also interfaces with most CAD and FEA applications, enabling for a flexible workflow.

Find a more comprehensive list of the software’s .

Related Content

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Troubleshooting thermoplastic composite stamp forming

Understand the basic science of TPC stamp forming, a manufacturing process steadily gaining momentum in aerospace and mobility applications thanks to its rapid forming, short cycle times and automated methods.

-

Next-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.