Turkish Aerospace, Boeing partner to produce thermoplastic composites

Per the partnership, Boeing will provide technical support to establish a fully automated facility in Turkey for the production of thermoplastic aerospace components, as well as training technical personnel.

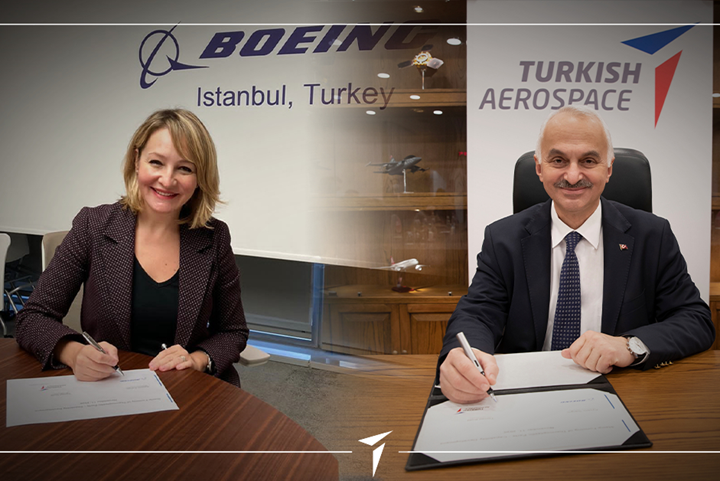

Photo Credit: Turkish Aerospace

R&D company, (Ankara, Turkey) announced on Nov. 12 a partnership with Boeing (Chicago, Ill., U.S.) that aims to develop thermoplastic manufacturing capabilities in Turkey, as part of the region’s continued effort to develop high-tech products locally. For the collaboration, Boeing will provide technical support for Turkish Aerospace to establish a fully automated facility for the production of thermoplastic materials for the aerospace industry.

“We are very excited to sign a new cooperation with our strategic partner Boeing,” Turkish Aerospace CEO, Professor Temel Kotil says. “We look forward to continue increasing the direction of new production technologies in the aviation sector. As the company that guides and leads the most important projects of Turkey, we will have high-quality thermoplastic part production, which will reduce cost significantly.”

Aysem Sargin, managing director Boeing Turkey, adds that this agreement adds a new dimension to the longstanding partnership between Turkish Aerospace and Boeing. “It also expands the existing technology collaboration between Boeing and Turkey under the National Aerospace Initiative (NAI), which is Boeing’s investment plan for Turkey, announced in 2017. This is a reflection of our continued commitment to the country and to our partners.”

Turkish Aerospace and Boeing’s research is focused on designing high-quality thermoplastic parts in a high-capacity rapid production system for aerospace use. Initial results show that High Efficiency Affordable Rapid Thermoplastic (HEART), can reduce the production cycle and process costs by 30% compared to conventional composites.

This partnership will include the training of technical personnel to develop local expertise in this field and enable Turkey to produce thermoplastics that meets the highest global standards.

Related Content

-

Thermoplastic composites: Cracking the horizontal body panel nut

Versatile sandwich panel technology solves decades-long exterior automotive challenge.

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.