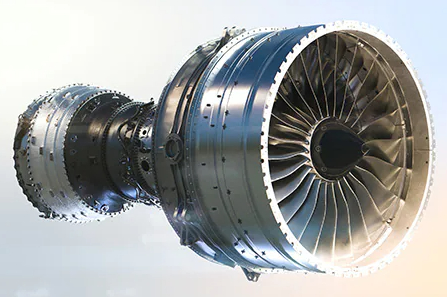

Spirit AeroSystems named exclusive nacelle provider for Rolls-Royce Pearl 10X engine

Spirit’s advanced digital techniques, proprietary tools and composite and fabrication capabilities will be leveraged to enable delivery on all program requirements.

Rolls-Royce Pearl 10X engine family. Photo Credit: Rolls-Royce

Spirit AeroSystems (Wichita, Kan., U.S.) has entered into an exclusive agreement with (London., U.K.) to design and build the next generation of slim-line nacelles for the company’s newest engine, the Pearl 10X. The company’s brand new, ready-for-assembly ultra-slim nacelle reportedly improves laminar flow to optimize aircraft performance and acoustic impedance. The Rolls‑Royce work is another example of Spirit’s diversification strategy to grow its presence in the business jet market.

“Leveraging our decades of manufacturing experience with metallic and composite structures, Spirit is diversifying our business to bring innovative products to business jet customers, and our program with Rolls-Royce is a great example of that work,” says Katie Wesbrooks, senior director of Business & Regional Jets, and Strategic Programs at Spirit AeroSystems. “We’re excited to embark on this new program with Rolls-Royce as we continue to advance programs within the business jet market.”

According to Rolls-Royce, the Pearl 10X is a highly powerful and efficient engine, enabling operators to travel ultra-long distances at nearly the speed of sound for outstanding airport accessibility. For production, Spirit says it will leverage its composite and fabrication capabilities at its Wichita facility to support the program. Spirit will provide competitive aerostructures with kits that Rolls-Royce can seamlessly install during final assembly, helping to speed up processes.

As a provider of engine strut and nacelle products for all kinds of aircraft, Spirit notes that it learned from its work on the BR725, a Rolls-Royce engine, to create process improvements to confidently produce the volume of nacelles required for the new Pearl 10X program. The company also applied advanced digital design techniques to continue to advance the affordability of robotic manufacturing and industrialization.

Related Content

-

Plant tour: Airbus, Illescas, Spain

Airbus’ Illescas facility, featuring highly automated composites processes for the A350 lower wing cover and one-piece Section 19 fuselage barrels, works toward production ramp-ups and next-generation aircraft.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

The next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?