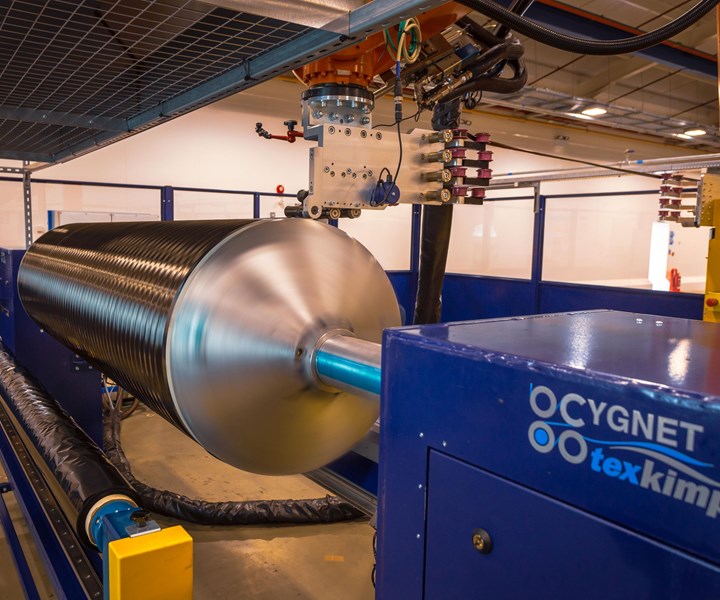

Solvay showcases low-cost prepreg and parts approach using Cygnet Texkimp filament winder

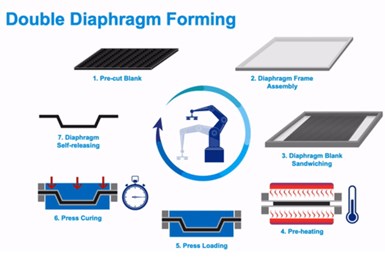

High-speed, tailored preforms are used with Solvay double diaphragm forming (DDF) and compression molding to produce cost-effective, medium-volume auto and aero parts.

Composite materials and technology supplier Solvay (Alpharetta, Ga., U.S.) has installed a four-axis robotic filament winding machine designed and built by fiber handling specialist and custom machinery manufacturer Cygnet Texkimp (Cheshire, U.K.) to make low-cost prepreg material and composite parts.

The bespoke winding machine was installed at , an R&D facility based in Heanor, where the company develops new technologies and processes for the adoption of composites in high volume markets including automotive and aerospace.

High-speed, multi-layer preforms

SOURCE | Solvay

The filament winder was designed by Cygnet Texkimp to enable production of large composite material sheets, or preforms, which can be molded using Solvay’s technology and compression molding. The goal is to create cost-effective exterior parts for the automotive industry, including hoods and trunk lids.

“The machine we developed is, in effect, a semi-automated drum winder,” explains Cygnet Texkimp managing director Luke Vardy.​ “B​​ut unlike traditional machines of this kind, it is capable of winding fiber in a much wider range of angles, providing customers with greater flexibility in tailoring material properties within multi-layer preforms.”

The winder is capable of winding at a fiber speed of up to 100 meters/minute and has been built to accommodate a mandrel spanning 2.2 meters in length by 0.6 meters in diameter, to produce preforms sized up to 2 square meters. The finished wind is sliced from the mandrel and trimmed to size using an integrated, automatic cutting unit before being transported to the next stage of processing on a dedicated transfer table.

“Cygnet Texkimp worked closely with us to develop a highly controlled and efficient process that removes a lot of the labor requirement and allows us to show our customers how they can produce carbon fiber prepreg quickly, cost-effectively and competitively using our resins and materials,” said Richard Russell, Process Engineer at Solvay. “For the automotive market in particular, this is a very interesting alternative way to make high-performance composite parts in medium volumes.”

Constant tension for spread tow

The winder takes dry fibers, or tows, from an integrated, four-position driven creel, and feeds them onto an application head. The driven creel controls fiber tension throughout the process. This ensures consistent spreading despite variations in fiber speed which occur throughout the winding process.

Solvay has demonstrated double diaphragm forming using a filament-wound tailored preform, hot compression molding and matched metal tools for a BMW M4 GTS hood. Source | Solvay

The four tows are spread over the application head to create a 50-millimeter wide consolidated sheet or tape onto which Solvay’s resin system is applied, immediately before it is laid onto the mandrel.

Cygnet Texkimp’s design incorporates a resin metering system to mix Solvay’s advanced resins at the point of application, and in doing so eliminates the issue of pre-mixed resin curing before application or needing to be stored under special conditions.

Solvay has also worked with BMW (Munich, Germany) to demonstrate production of an M4 GTS hood using diaphragm forming of filament wound carbon fiber preforms.

For more details, see Solvay’s (p. 7).

Related Content

Aerospace prepregs with braided reinforcement demonstrate improved production rates, cost

A recent time study compares the layup of a wing spar using prepreg with A&P’s TX-45 continuous braided reinforcement versus traditional twill woven prepreg.

Read MoreRWC completes prototype radome using Renegade NCAMP-certified composite

Completed prototype for Georgian Aerospace uses a low-dielectric epoxy prepreg on quartz fabric, which has passed radio frequency testing with results equivalent to traditionally higher-cost, low-dielectric matrix options.

Read MoreTeijin Carbon, A&P Bimax TPUD braided fabric meets scalable composites manufacturing goals

A combination of Teijin Carbon’s UD thermoplastic tapes and A&P Technology’s braided fabrics translates into a PAEK biaxial fabric with minimal crimp, high drapability and other rate-enabling qualities.

Read MoreTextile machinery, NCFs provide sustainable processing options

CAMX 2024: Karl Mayer is returning to CAMX with a focus on fabric- and fiber-handling equipment, in addition to its application development services.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More