Quarantreat offers fast-build medical isolation studio for COVID-19 containment

Rapid dispatch design uses LitePan composite structural insulated panels and LiteTex thermoplastic composite laminates.

There is now a global need to isolate individuals who either have been infected with the virus causing COVID-19 or are suspected to have been infected but do not exhibit serious symptoms. Such containment facilities should be comfortable yet cost-effective, enabled by rapid and sustainable construction technology.

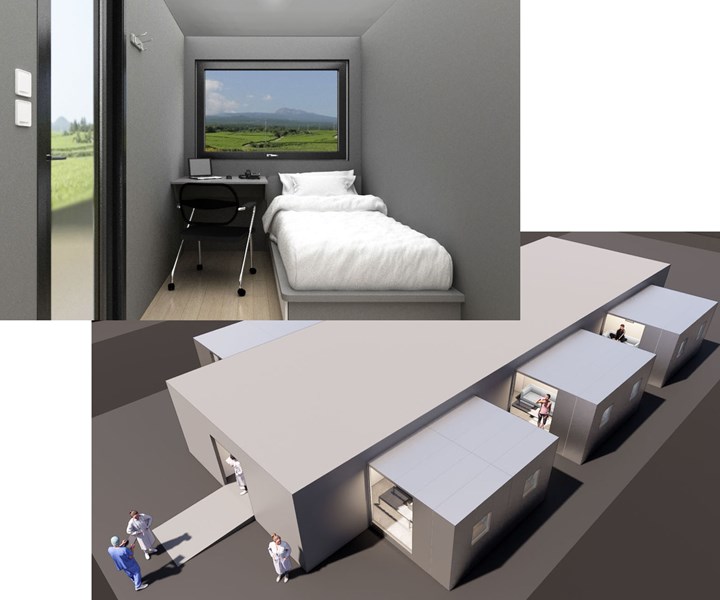

Axia Materials (Hwaseong, South Korea), a polymer engineering and materials innovation company, has announced together with its partners Staus (Busan, South Korea), a modular housing producer, and construction technology startup Dymaxon (Seoul, South Korea), the move-in ready Quarantreat Medical Isolation Studio (MIS) () to fill this need anywhere in the world.

Completed Quarantreat MIS units in the Staus factory. SOURCE | Axia Materials

Quarantreat MIS is a medical isolation studio featuring a hotel-class interior and an optional Negative Pressure Ventilation (NPV) system to control airborne pathogens. It is designed for rapid installation as a quarantine system for low-symptom or symptom-free COVID-19 infected or potentially infected patients. All the equipment necessary to live comfortably for a duration of a few weeks are fit snugly into a compact 12.5-square meter (135 square feet) living compartment. This includes full shower bathroom, furniture, HVAC with active air exchanger and Internet of Things (IoT) functionality; built-in TV, computer, mini-fridge and NPV options are available.

Designed for rapid dispatch anywhere on the planet, two Quarantreat MIS units fit inside a 40-foot high cube sea freight container or in the hold of a C-130 cargo airplane. Upon delivery, the only set-up required is to connect the electricity, plumbing and optional communications network. Many Quarantreat MIS units can be arranged into a Quarantreat Fleet together with a centralized service center to provide food service and hospitality supervision.

The Quarantreat GS is an alternative collection of modified Quarantreat units assembled into a coordinated Grid System to create a medical Intensive Care Unit (ICU). The grid-wide standard NPV system controls airborne pathogens, and the built-in IoT and smart house functions of each Quarantreat unit can be integrated into patient status monitoring equipment (not provided) to keep the medical team apprised of the patients’ conditions at all times.

Quarantreat GS for quick-build intensive care unit (ICU) with standard, grid-wide negative pressure ventilation (NPV) system. SOURCE | Axia Materials

LitePan and LiteTex composite technology

LitePan C-SIPs (composite structural insulation panels) for Quarantreat MIS. SOURCE | Axia Materials

Integral to the design and performance of the Quarantreat is the use of LitePan Composite Structural Insulated Panels (C-SIPs) that provide the structural integrity of the unit, as well as airtight sealing and thermal insulation, which guarantee low operational costs for climate and pressure control.

All materials used in the construction of the Quarantreat product line have been rigorously tested for safety in a living environment. Tests cover fire safety, structural integrity and chemical emissions. LiteTex, the composite laminate for LitePan that gives the panel its strength and air-tight properties, exhibits no measurable volatile organic compound (VOC) emissions — an essential requirement for medical units — and the LitePan structure system has a demonstrated performance of 0.24 air changes at 50 Pa, n50 [/h], which is a result 4 times better than the world-leading German passive house standard.

Because of this airtight sealing property, the transportable NPV system used in Quarantreat MIS can efficiently sustain the required pressure differential while maintaining an air change rate in the range of 12 to 40 times per hour with a library-acceptable noise level less than 40 decibels. The hospital regulation for NPV is greater than 12 air changes per hour.

Interior and exterior panel surface laminates assure conformance with fire safety standards. The Quarantreat MIS boasts R24 insulation value, ASTM E84 Class ‘A’ flame spread on interior and exterior wall and ceiling surfaces, 60 minute ASTM E119 resistance to interior fire and an easily cleaned anti-bacterial interior finish.

After the crisis phase of the pandemic has subsided, Quarantreat can be re-purposed for use as a modular hotel, dormitory, veteran housing, temporary shelter or other immediate and affordable accommodation functions.

“Our composite building technology enabled us to develop the Quarantreat MIS units to be rapidly manufactured at low cost while exhibiting light weight and air tight sealing,” says Axia Materials CEO Justin Jin. We are now producing 300 units per month and already filling our first order from the Singapore government. We are also receiving inquiries from the U.S., Canada, France, Japan and Southeast Asian countries. We are proud to utilize our novel composite technologies to deliver an immediate architectural solution to address the unique challenges of this pandemic.”

Partner companies

Project leader Axia Materials Co., LTD. (www.litetex.com / ) is a thermoplastic composite laminates and composite structural insulated panel (C-SIP) manufacturer in South Korea. Their composite structural insulated panel building system has been used to construct affordable, sustainable housing in Europe, Asia, and North America. In 2016, a US military barracks was assembled in Kuwait using this technology. Read more in “Thermoplastic composite panels deliver affordable housing solutions”.

is a South Korean modular house company having decades of modular systems business experience in cruise ship cabins. All Quarantreat units are manufactured in Staus’ factory located in the port city of Busan, South Korea.

is a Contech startup in South Korea highlighting IoT, kinetic architecture and digital based mass manufacturing technologies. Dymaxon developed the modular design and grid operation system for the Quarantreat product line.

For more information, contact Justin Jin justin@axia-m.com

Related Content

Swedish parking garage to incorporate decommissioned wind blades

Architect Jonas Lloyd is working with Vattenfall to design the multistory building with a wind blade façade, targeting eco-friendly buildings and creative ways to remove blades from landfills.

Read MoreComposites end markets: Infrastructure and construction (2024)

Composites are increasingly used in applications like building facades, bridges, utility poles, wastewater treatment pipes, repair solutions and more.

Read MoreU.S. grant is awarded for patented SIP composites formwork system

ConTech stay-in-place (SIP) technology, made from recycled composite materials, replaces the use of reinforcing steel in the construction of flat, elevated concrete surfaces.

Read MoreRenco USA brings Lego-style composite building system to construction

After more than a decade dedicated to R&D, evaluation and testing, the company has proven its MCFR building system in a Lakewood Village project in Florida.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More