Partnership promotes Hypetex colored carbon fiber materials to North American market

Massachusetts-based CompositesTech will perform sales and marketing for the Hypetex fiber reinforcement portfolio and introduce it to new customers and markets.

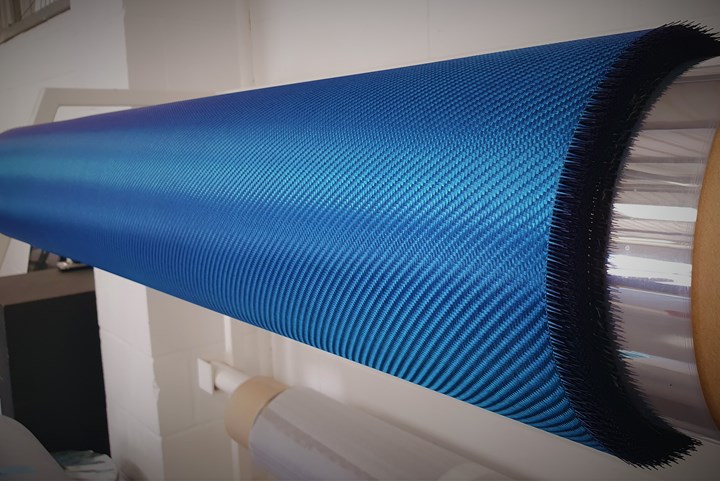

Photo Credit: CompositesTech LLC

On May 10, (London, U.K.), a manufacturer of colored reinforcements and advanced materials, reached an agreement with (Amesbury, Mass., U.S.), a technical and business development leader of composite materials and services. With this partnership, CompositeTechs will perform sales and marketing for the Hypetex portfolio which consists of technical colored carbon fiber materials and other reinforcements and has been made available to the North America market.

“CompositeTechs is committed to delivering the best quality and sustainable solutions to the composites industry,” says Marc Cohen, Hypetex CEO. “Their ability to reach the right members within the community make them a great partner as we bring Hypetex advanced colored materials to North America.”

Hypetex offers carbon fiber and other reinforcements in a wide variety of colors using a water-based, environmentally friendly process that has no effect on the material’s required properties. Hypetex materials are available in a variety of colors and fiber coating attributes (i.e., UV protection and thermal emissivity) which the company says have not been previously obtainable for composites. Further, the naturally colored fiber reinforcements offer users a high 3D aesthetic straight from the mold, reducing post-processing costs.

“We are excited about this relationship with Hypetex to bring their innovative products to the North American marketplace,” says Mike Favaloro, president of CompositeTechs. “One of our major focuses has been on improving sustainability in the advanced materials industry; that includes reducing the environmental impact of the manufacturing process on local communities at a net-zero cost or cost savings, while increasing both product performance and jobs for the community. The Hypetex products, while they are manufactured using a sustainable, water-based process, also offer the same potential to our friends in North America.”

Favaloro points to the elimination of painting booths as well as processing capabilities for small to large structures while simultaneously creating an improved aesthetic surface. “Further enhancements, such as providing UV protection for aramid fibers to extend performance in outdoor environments, and managing the thermal emissivity of composite structures, are great supplements for the toolkit of composite designers,” he adds. “We are excited to be able to introduce Hypetex to both our existing and new customers and markets.”

Related Content

-

The potential for thermoplastic composite nacelles

Collins Aerospace draws on global team, decades of experience to demonstrate large, curved AFP and welded structures for the next generation of aircraft.

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

From the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.