NC State University study kick-starts carbon fiber production process

Addition of chemical additives, glucaric acid and mucic acid, into precursor PAN material decreased energy requirements for conversion into carbon fiber five-fold.

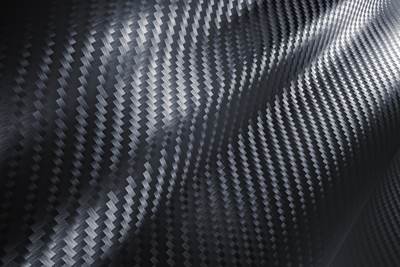

Researchers work on making carbon fiber more efficiently. Photo Credit: Debjyoti Banerjee.

In a new reported in the Journal of Applied Polymer Science, North Carolina (NC) State University (Raleigh, N.C., U.S.) researchers have found a way to improve the energy efficiency of part of the process for making carbon fiber.

Under this study, results were reported from an experiment where they added two biologically derived chemicals found in certain fruits into a precursor material for carbon fiber. They found that with the addition of the two chemicals, starting the chemical conversion process of making carbon fiber required less energy. The chemicals are sugar acids called glucaric acid and mucic acid.

“There is an increasing demand for carbon fiber, and when it comes to low-cost fiber, one of the leading applications is for use as a structural material in vehicles,” says Ericka Ford, assistant professor of textile engineering, chemistry and science at NC State. “In this study, we found that by adding the two chemicals into the precursor material, we can potentially reduce the amount of energy required to complete one stage of the manufacturing process for carbon fiber, and help bring down some of the cost.”

Before using the lab chemicals, researchers turned to computer modeling to get a preview of what would happen when they added the two chemical compounds to the precursor material. Their interest in the chemicals was initially piqued after one of them, glucaric acid, was listed by the U.S. Department of Energy (DOE) as a chemical of industrial significance.

“We were interested in understanding how these chemicals would interact with the precursor material, so using computer models and simulations we were able to look at their interaction parameters before we even started lab work,” adds study co-author Hannah Dedmon, an NC State graduate student. “We’re able to slow things down and zero in to look at atomic-level details, which we are blind to in the lab.”

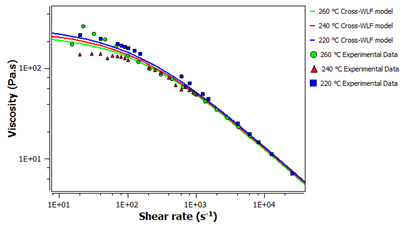

From there, they experimentally tested making the precursor material — polyacrylonitrile (PAN). First, a gel-like material that has a consistency similar to honey was produced, then pushed through a tiny needle to transform into a very fine filament. Next, the PAN filaments were heated to very high temperatures, eventually converting into a structure that forms the basis of carbon fiber.

Addition of the chemical additives reportedly decreased the energy required to start the chemical process of making the carbon structure from PAN five-fold. Researchers say that could also reduce the overall cost of that step of the manufacturing process by making the reaction faster.

“These are small molecules with functional groups that are capable of starting the reaction much more efficiently than if it hadn’t been in the fiber,” says the study’s lead author Debjyoti Banerjee, doctoral candidate at NC State.

Next, researchers plan to look at other additives, as well as possible use computer models to predict which ones might get the most bang for their buck. “We are interested in looking at other natural products that we could add to PAN fibers and influence their usefulness for conversion into carbon fiber,” Ford adds.

The study, “Cyclization kinetics of gel-spun polyacrylonitrile aldaric-acid sugars using the isoconversional approach,” was authored by Banerjee, Dedmon, Ford, Farzin Rahmani and Melissa A. Pasquinelli. It was funded by the NC State Chancellor’s Innovation Fund.

Related Content

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreAviation-specific battery system uses advanced composites to address electric, hybrid flight

BOLDair’s composite enclosure, compression structures and thermal runaway management enables high-performance electric energy storage.

Read MoreRead Next

Thermoplastic tapes reinforced with textile-based PAN carbon fiber

IACMI project trials inline production of thermoplastic tapes reinforced with textile-based PAN carbon fiber.

Read MoreMAE Spa receives funding to build PAN precursor plants in China

New financial support enables the company to complete order for design and construction of new carbon fiber precursor production facilities.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read More