Mercedes-AMG GT4 race cars now equipped with Bcomp natural fiber composite bumpers

Bcomp works with engineering specialist HWA to phase in natural fiber bumpers, replacing carbon fiber versions. Analyses report a 90% reduction in material emissions and thermal energy recovery potential.

Mercedes-AMG GT4 with natural fiber-reinforced composite bumper. Photo Credit, all images: Bcomp, HWA

Sustainable lightweighting company, Bcomp (Fribourg, Switzerland), is now supplying its high-performance natural fiber technologies to (Affalterbach, Germany) — development partner of (Baden-Württemberg, Germany) — for the new front bumpers on Mercedes-AMG GT4 race cars. Set to be phased in over the coming weeks, Bcomp’s bodywork solutions will provide a sustainable alternative to the GT4’s existing carbon fiber panels, offering equivalent mechanical performance in stiffness and weight and improving safety.

The new bumper uses Bcomp’s well-known ampliTex and powerRibs technologies, which harness the natural advantages of flax fiber. The powerRibs reinforcement grid uses the high specific bending stiffness of flax to build up height efficiently, Bcomp points out, boosting the flexural stiffness of thin-walled shell elements significantly. The new bumpers are also safer in the event of a crash or collision and decrease the risk of punctures, with powerRibs confining the damage zone and minimizing debris.

“Development coincided with the height of the pandemic, and it was challenging at times,” Christian Fischer, CEO and co-founder of Bcomp, comments. “In fact, our first bumper build, design fitting, optimizations and revisions were all achieved during the pandemic — a testimony to the hard work and persistence of all involved. It has been a pleasure to work with the HWA team and we look forward to investigating further applications in race and high-performance road cars.”

A full sustainability analysis concluded that the new bumper offered a total material emission reduction of 90% when compared to the carbon fiber part as well as an 85% reduction of CO2 emissions from cradle-to-gate, considering all production steps from raw material to final part. Bcomp’s materials not only reduced the part’s carbon cost, but they also introduced the option of thermal energy recovery. Since the new bumper is full natural fiber, it is said it can recover approximately 80% of the energy stored in the part into renewable energy, resulting in a process without hazardous carbon waste or parts that need to go into landfill.

Reverse-engineered from HWA’s original, the natural fiber bumper’s design has been collaboratively optimized over the past 12 months. To ensure that the bumper met all racing regulations and requirements, the HWA team performed extensive mechanical testing and validation. On the HWA testbench, the stiffness of the complete frontend of the Mercedes-AMG GT4 was measured, simulating the aerodynamic drag and front diffusor downforce. The tests were conducted with a carbon fiber bumper as benchmark and afterwards with the natural fiber bumper, validating that the newly designed part performs on the same high-performance level.

Furthermore, part of the project was to validate the HWA inhouse paint processes with ampliTex and powerRibs, optimizing the A-surface quality of the part up to a level that meets the quality standards of HWA and Mercedes-AMG motorsport. Production of the old carbon fiber bumpers has now ceased, and all customer teams will receive the new Bcomp version with their next orders.

Bcomp says its technologies are already used in 16 racing series around the world, but their applications are not restricted to motorsport. From automotive interior panels and bodywork to luxury yachting and the European Space Agency’s (ESA’s) natural fiber satellite panels, Bcomp’s technologies are relied upon wherever weight, stiffness and sustainability are important. With the GT4 cars closely based on their road-going counterparts, these racing projects open up opportunities for future high-performance road applications.

“The topic of sustainability plays a major role in our company. Several awards for our efforts in the area of environmental protection are proof of this,” Anne Mink, manager technical development, HWA AG, adds. “Part of our sustainability concept is to evaluate and optimize the product life cycle with regard to environmental aspects as early as in the product development stage. Furthermore, it is our aspiration to constantly adapt our long-standing engineering know-how to current environmental requirements in order to be able to offer our customers sustainable products at the highest technological level. In Bcomp, we have got a development partner with extensive experience in sustainable materials. The result of our cooperation shows that technologically equivalent components can be created from alternative materials.”

Related Content

Biomaterials make strides toward composites sustainability

A compilation of trends in development or application of natural fibers, bio-based resins and more showcases industry players, educational institutes and global projects.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreComposites end markets: Sports and recreation (2025)

The use of composite materials in high-performance sporting goods continues to grow, with new advancements including thermoplastic and sustainability-focused materials and automated processes.

Read MoreDITF Denkendorf advances sustainable carbon fibers, oxide fibers for CMC and more

The German Institutes of Textile and Fiber Research are targeting more sustainable carbon fiber via low-pressure stabilization and bio-based precursors, and working with Saint-Gobain to commercialize oxide ceramic fibers for CMC.

Read MoreRead Next

BMW Group invests in Bcomp for high-performance natural fiber components

Collaborative partnership in motorsport moves to the next level for the use of renewable raw materials for future vehicle model components, and joint R&D materials work for production vehicles is underway.

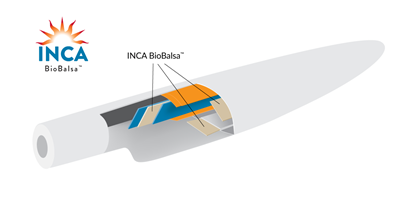

Read MoreINCA Renewtech to build advanced biocomposites manufacturing facility in Alberta, Canada

The fiber processing and composites manufacturing facility will ramp up INCA’s production of highly refined short and long fibers to substitute increasingly scarce balsa wood in boats, wind turbine blades, rail and automotive.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More