Bcomp developments continue to drive natural fiber toward scalability in motorsports

The Swiss sustainable lightweight manufacturer announces new developments for vehicle interiors, sustainability analyses results for ampliTEX and powerRibs reinforcements and recent technology recognition.

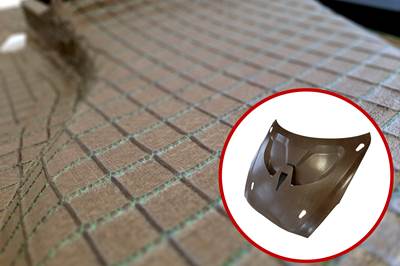

Porsche Motorsport’s Cayman 718 GT4 CS natural fiber interior. Photo Credit: 2021 Dr. Ing. h.c. F. Porsche AG

Bcomp (Fribourg, Switzerland), a natural fiber reinforcements manufacturer for high-performance applications ranging from race to space, has announced several new developments, from the addition of natural fiber interiors to racecars, next steps for McLaren’s Formula 1 (F1) racing seats and recent recognition for the company’s innovations.

Photo Credit: 2021 Dr. Ing. h.c. F. Porsche AG

Following the successful delivery of a full natural fiber composite bodywork kit for the doors and rear wing of Porsche Motorsport’s Cayman 718 GT4 CS back in October 2020, Bcomp has now outfitted the vehicle with a more sustainable interior to match. Nine interior carbon fiber parts — including the air channels, consoles, instrument cluster, glovebox and roof panel — were reverse engineered by Bcomp and replaced with natural fiber options using ampliTEX and powerRibs reinforcements, which are able to minimize vibrations as much as 250%. Visual components were also painted with a matt lacquer to match the finish of the GT4 CS series rear wing.

As part of the project, Bcomp also conducted a full sustainability analysis comparing the natural fiber composites to the conventional carbon fiber parts, which revealed the former offers a 94% reduction in material emissions and a 90% reduction in cradle-to-gate emissions.

The components underwent extensive endurance racing testing at the Nürburgring Endurance Series in September 2021.

“Alongside these primary benefits, our natural fiber technologies also improved vibration damping and deliver a splinter-free crash behavior due to their inherent mechanical properties and design,” notes Christian Fischer, CEO and co-founder at Bcomp. “Given the popularity of race-to-road technology transfer — and the similarity between GT4 and road-going sportscars — this proves the possibility of volume road applications for our technology. We look forward to continuing our work with Porsche Motorsport and exploring new possibilities and applications for sustainable composites in racing and beyond.”

The next step has also been taken with McLaren Racing’s (U.K.) use of natural fiber textiles in its F1 racing seats since collaborating with Bcomp in 2020. The seats were used for the first time at the 2021 British Grand-Prix, when McLaren’s Lando Norris piloted the seat to fourth place.

McLaren Racing at the Grand-Prix 2021. Photo Credit: McLaren Racing

According to Bcomp, sustainability analyses have shown that the natural fiber composites enabled the racing team to save up to 85% of CO2 emissions on Lando’s seat. Moreover, McLaren Racing has also found incorporating ampliTex has improved its timing stands and engineering islands, leading to a significant reduction of 3,450 kilograms (~7,606 pounds) in traveling freight; this is especially important, McLaren notes, when considering the team’s equipment moving between Grand Prix locations.

Becoming one of four finalists for the Trophées PME 2021 is another development that continues to reflects Bcomp’s continuous advancements in the natural fiber space, since the start of the company in 2011.

“When founding Bcomp, we selected Fribourg as the location for our facility because the city and its surroundings are quickly becoming a hub for innovation, know-how and forward-looking companies,” says Fischer. “The connection to all parts of Switzerland allow us to attract the highly qualified teammates we need from all the main population centers in western and central Switzerland. To be a finalist of the Trophées PME is yet another sign that we have grown out of our startup phase, and is the result of a great team effort over the past years.”

The prize-giving ceremony for the Trophées PME 2021 is taking place Nov. 17 at the Forum Fribourg.

Related Content

Revisiting the OceanGate Titan disaster

A year has passed since the tragic loss of the Titan submersible that claimed the lives of five people. What lessons have been learned from the disaster?

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreSulapac introduces Sulapac Flow 1.7 to replace PLA, ABS and PP in FDM, FGF

Available as filament and granules for extrusion, new wood composite matches properties yet is compostable, eliminates microplastics and reduces carbon footprint.

Read MoreOtto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read MoreRead Next

Natural fiber-intensive Aura EV concept car unveiled

The all-electric vehicle concept was developed with natural fiber composite body panels designed by BAMD Composites with Bcomp materials.

Read MoreComposites Evolution, Bcomp launch Evopreg ampliTex flax-epoxy prepregs

Compatible with Bcomp’s powerRibs reinforcement grid, the family of natural fiber materials drives enhanced stiffness, lightweight and a reduced footprint for motorsports and high-performance automotive applications.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More