CRP USA achieves AS9100 Rev. D certification

The certification enables CRP’s manufacture of 3D-printed aerospace products from its customer's component design data.

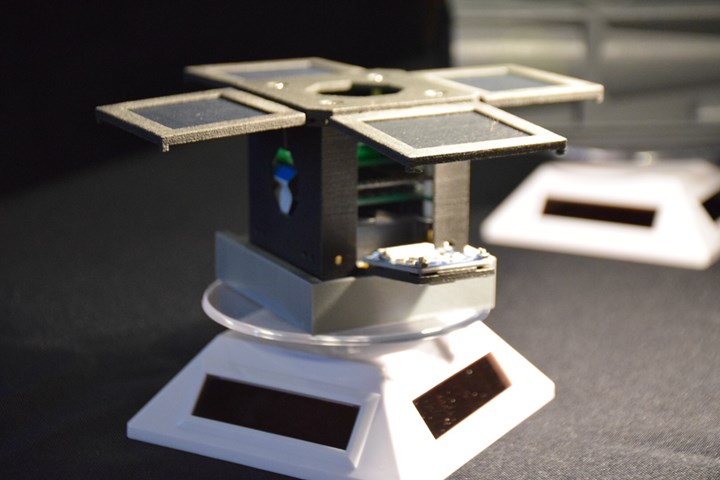

Photo Credit: Mini-Cubes

CRP USA (Mooresville, N.C., U.S.), additive manufacturing and high-performance composite materials company, announced that it has recently achieved AS9100 Rev. D certification for the manufacture of 3D-printed aerospace products from its customer's component design data. AS9100 is the international Quality Management System standard for the aviation, space and defense (AS&D) industry, created by the IAQG (the International Aerospace Quality Group; Brussels, Belgium) and is said to signify CRP USA’s ongoing commitment to meeting and exceeding increasingly stringent industry requirements for aerospace related products.

"We have taken our expertise in additive manufacturing solutions to new heights to produce parts for the most demanding sectors as aerospace and defense," says Stewart Davis, director of Operations, CRP USA. “Our team is working alongside key space industry leaders, supplying value-added high-performance 3D-printed products to meet their needs. AS9100 Rev. D certification reflects our dedication to achieving the highest standard of customer satisfaction; moreover, it is a further demonstration of the effectiveness of additive manufacturing and use of Windform as structural materials for space and aerospace applications.”

Related Content

-

Syensqo composites demonstrate titanium replacement on Boeing MQ-25 Stingray

Validation of integrating Cycom 5250-4HT prepreg into the UAV’s exhaust nozzle structure underpins the material system’s use in other high-temperature aerospace applications.

-

Converting carbon fiber for UHTCMC to 3500°C

Advanced Ceramic Fibers LLC demonstrates ultra-high temperature ceramic matrix composites using SiC and other metallic carbides for applications in aerospace, defense, energy and more.

-

TenCate Advanced Armour renamed to Integris Composites

With its rebranding, Integris maintains the ability to develop, test and manufacture ballistic armor and survivability solutions while expanding into new markets where composite solutions can be advantageous.