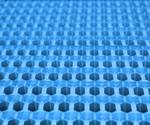

BCP launches e-commerce platform for honeycomb composite panels

Bespoke Composite Panels’ products are manufactured at various bespoke dimensions and thicknesses, for applications in rail, marine and other industries.

Bespoke Composite Panels (BCP; Cambridgeshire, U.K.), an aluminum honeycomb composite panel manufacturer, has announced the launch of its new e-commerce platform selling its standard composite panels direct from its website for same-day dispatch.The 600-millimeter by 600-millimeter aluminum honeycomb composite panels are available in five thicknesses ranging from 6 millimeters to 25.4 millimeters.

BCP manufactures composite panels for various bespoke dimensions and thicknesses, and says its goal with the launch of the e-commerce platform was to meet the demands of customers for smaller composite panels with a quick turnaround. BCP aims to expand its online product range to offer additional dimensions.

Aluminum honeycomb composite panels have been used for a variety of products including rail and marine interiors and furniture, display structures, vacuum tables, architectural products and flight simulation decks for pilot training. Benefits are said to include light weight, durability, a longer lifetime than wood, low energy consumption caused by low weight, low maintenance and refurbishment costs and less rework due to tighter tolerances. The panels are also reportedly easier to install than panels of other materials.

Related Content

-

JEC World 2024 highlights: Thermoplastic composites, CMC and novel processes

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

-

Hybrid process marries continuous, discontinuous composites design

9T Labs and Purdue applied Additive Fusion Technology to engineer a performance- and cost-competitive aircraft bin pin bracket made from compression-molded continuous and discontinuous CFRTP.

-

Combining multifunctional thermoplastic composites, additive manufacturing for next-gen airframe structures

The DOMMINIO project combines AFP with 3D printed gyroid cores, embedded SHM sensors and smart materials for induction-driven disassembly of parts at end of life.

.jpg;width=70;height=70;mode=crop)