High-speed engine blade manufacturing

High-speed video of GEnx engine blade manufacturing at CFAN offers a great look at the complexity of composites manufacturing.

It's well understood that composites manufacturing in general can be a complex and complicated process. Composites are, after all, the only material that that is made as the part is made, and when you consider the host of fibers, resins and manufacturing processes available, the complexity can be a blessing and a curse.

For a glimpse of that complexity, it's hard to beat this video of the in San Marcos, TX, US, making GEnx aircraft engine fan blades. It's a fascinating and quick tour of the materials, processes, equipment and people required to make one blade. And I can't help but wonder what this process might look like in 10 years.

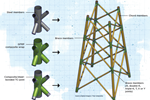

GEnx carbon fiber composite fan blades.

Related Content

-

The next-generation single-aisle: Implications for the composites industry

While the world continues to wait for new single-aisle program announcements from Airbus and Boeing, it’s clear composites will play a role in their fabrication. But in what ways, and what capacity?

-

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

-

Otto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.