Cutting time for composites design allowables

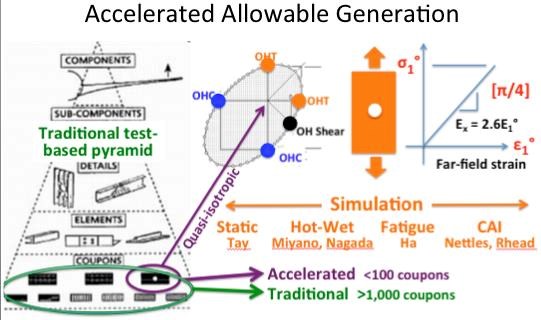

New approach by Dr. Stephen Tsai and Daniel Melo promises to reduce the required number of tests from 1,000 to mere dozens, providing results in days vs. months and at much lower cost.

New vs. traditional approach to design allowables.

SOURCE: Dr. Stephen W. Tsai and Jose Daniel D. Melo.

HPC reported on this new approach in the July issue: “Overnight design allowables? An invariant-based method for accelerating aerospace certification testing.” For more details and the full series of charts and graphs, see the white paper from Dr. Tsai and Daniel Melo posted on CW’s White Papers page.

Dr. Tsai comments, “The recognition of invariants that can significantly simplify design and testing of composites structures was discovered by Daniel and me by accident. The number of tests for design allowable generation can be reduced from one thousand to a few dozen if not fewer. More importantly, key tests can be made a matter of hours instead of days, weeks or months.” He adds that the only stiffness data needed is the value of trace, a sum of the diagonal components of the stiffness matrix. “For strength, one tensile or compressive strength of open hole coupons at room temperature can be sufficient to generate allowables, and the accelerated testing of fatigue strength can also be done based on the shift factor of viscoelastic behavior of composites.”

To put it more in layman’s terms and get a critical review, I asked Dr. Rik Heslehurst to read and comment on the white paper. Heslehurst is a former aeronautical engineering officer in the Royal Australian Air Force (RAAF), in charge of material and process engineering for almost two decades. He also instructs advanced composite engineering courses for Abaris Training (Reno, Nevada) and has consulted for a wide variety of companies including Boeing, the U.S. Air Force, Lockheed Martin and Bombardier. Heslehurst’s response:

"The basic premise is that all composite materials (plies and laminates) have a stiffness relationship that is essentially invariant (statistically low variation). This invariant term is called TRACE. With knowledge of the axial longitudinal modulus value for any composite material the TRACE factor can be determined and the resulting stiffness matrix of a ply and thus a laminate can be determined. This approach is a significant and positive step in reducing the cost of determining materials allowables.

I would caution, however, that the assumptions made, such as the major Poisson’s ratio as 0.3 and the derivation of the shear modulus term, require a sufficient knowledge of composite materials properties computation as well as design allowables generation — for example, the differences between that for unidirectional tape and cloth.

I believe that the development of the shift factors for open hole, environmental and fatigue is also a very positive step, and fortunately, there is now extensive materials data available on these effects to allow close comparison with simulated data.

I am encouraged by the approach and already see several applications in my own work that will allow early and rapid development of composite designs, but I would reiterate that a novice not use this approach without due understanding and caution."

The foundation of invariants and implications on composites design allowables testing will be covered extensively by several speakers in the upcoming Composites Durability Workshop 19 (July 27-29) hosted by Stanford University’s Department of Aeronautics & Astronautics (Stanford, Calif., USA).

Proposed advances that can simplify design allowables generation will be presented by representatives of Stanford, Wichita and other universities, as well as end users and the FAA. Potential issues in expanding the adoption of this approach will also be discussed and help in using tools and templates for one master ply will be available during and after workshop.

A formal technical paper, “,” has just been published online in the journal Composites Science and Technology.

Related Content

Plant tour: Aernnova Composites, Toledo and Illescas, Spain

RTM and ATL/AFP high-rate production sites feature this composites and engineering leader’s continued push for excellence and innovation for future airframes.

Read MoreWelding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

Read MoreOtto Aviation launches Phantom 3500 business jet with all-composite airframe from Leonardo

Promising 60% less fuel burn and 90% less emissions using SAF, the super-laminar flow design with windowless fuselage will be built using RTM in Florida facility with certification slated for 2030.

Read More“Structured air” TPS safeguards composite structures

Powered by an 85% air/15% pure polyimide aerogel, Blueshift’s novel material system protects structures during transient thermal events from -200°C to beyond 2400°C for rockets, battery boxes and more.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More