3-D preformed composites: The leap into LEAP

The LEAP jet engine is the next generation of the successful CFM56 engine for narrow-body aircraft which powers more than half of the commercial aircraft ordered in the past decade.

This short article is a sidebar to the feature article: "Albany Engineered Composites: Weaving the future in 3-D."

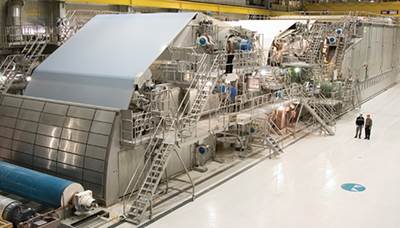

The LEAP jet engine is the next generation of the successful CFM56 engine for narrow-body aircraft which powers more than half of the commercial aircraft ordered in the past decade. Produced by CFM International (Evry, France and Cincinnati, Ohio) — a 50/50 joint venture of Snecma and GE, formed in 1974. Snecma/Safran (Paris, France) is responsible for the low-pressure fan sections and GE Aviation handles the high-pressure combustion core. LEAP reportedly will offer a 15 percent reduction in fuel consumption and CO2 emissions, the lowest operating cost (thanks to less maintenance and longer intervals between service) and an aircraft departure reliability of 99.98 percent. The 3-D woven resin transfer molded (RTM) composites developed by Safran and AEC are a key enabling technology in LEAP’s ability to achieve this high performance (see Fig. 2).

LEAP will use 18 carbon fiber-reinforced polymer (CFRP) blades that together weigh 168 lb/76 kg. The CFM56 has 36 titanium fan blades, totaling 330 lb/150 kg. Lighter composite blades produce less energy that must be absorbed in a blade-out situation, allowing a less massive containment system. Also, a less weighty fan disk can be used to hold the blades in place. The weight savings cascade through other structures for a total 1,000 lb/454 kg reduction per aircraft. The LEAP blade’s aero-acoustic 3-D swept geometry helps to reduce overall engine noise and to meet International Civil Aviation Organization’s (ICAO, Montréal, Québec, Canada) Chapter 5 noise regulations.

Bird impact was a limiting design factor for the fan blade. A challenge for the 128-inch/3m diameter fan in the precedingGE90 engine, bird impact is magnified in the LEAP engine because on its smaller 78-inch/2m diameter fan — the first for single-aisle aircraft to use composites — the smaller blades offer less area to absorb the same impact energy.

The 3-D woven preform developed by Snecma and Albany Engineered Composites (AEC, Rochester, N.H.) results in a composite blade without any inherently weak, unreinforced planes that could be susceptible to delamination failures — an advantage vs. laminates that feature traditional 2-D fabrics. As dictated by the design of the 3-D fiber architecture, “layers” in the blade are interconnected with fiber so that both the through-thickness and in-plane properties of the blade are fiber dominated. In various “zones” of the blade, there are different in-plane and out-of-plane loads experienced in service, and these zones each require unique 3-D woven architectures, tailored to meet their structural requirements.

In addition to the blades, three other LEAP parts use AEC 3-D woven RTM composites: fan case, platforms and spacers. Platforms form the flow path between blades, while spacers are effectively springs that keep the blade in position while the engine is not spinning. 3-D woven technology is being evaluated for additional fan module components and also for ceramic-matrix composite (CMC) applications.

Where fan cases have previously used a metallic ring with or without an aramid fiber over-wrap, the LEAP fan case — incorporating AEC’s contour weaving and 3-D preform technology — will be the first to integrate the containment into the case via a carbon fiber 3-D structure, eliminating separate manufacture, assembly and excess weight. The carbon fan case cuts weight 30 percent versus aluminum. The 3-D preform enables a shaped cross-section with an integral flange on each edge and meets stringent fan blade-out test requirements.

Related Content

3D weaving capabilities achieve complex shapes with reduced labor times, costs

JEC World 2025: The specialized engineered woven fabrics company displays film-infused 3D woven joints, woven TPS and woven composite 3D structures.

Read MoreWoven UD fabric enhances scalable carbon fiber options for infrastructure

CAMX 2025: Zoltek introduces PX35 woven UD fabric which bridges the gap between performance and affordability for retrofit and new build scenarios.

Read MoreDyneema launches woven composite fabric with UHMWPE fiber

Dual-layer structure of Dyneema core with a fully woven Dyneema face fabric resists abrasion and wear, offering durability under significant load conditions and after prolonged use.

Read MoreHighly tunable, woven lattice reinforcements target automotive structures

CAMX 2023: Startup Weav3D will be demonstrating its two collaborative automotive demonstrator parts and present two conference papers.

Read MoreRead Next

Albany International: Multilayer to multidimensional

Albany International (Rochester, N.H.) has a half-century of experience in producing multilayer technical textiles to meet demanding performance and cost expectations.

Read MoreAlbany Engineered Composites: Weaving the Future in 3-D

This 3-D weaver turned composite component supplier pursues a future in 3-D structures through continuous technology development.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More