Novel robotic layup features expand FPP automation toolkit

CAMX 2025: The Cevotec team is presenting latest advances in fiber patch placement through the SAMBA Series through physical displays, lab video footage and an educational session.

Share

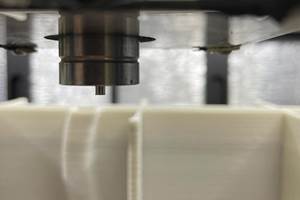

Steep edge layup close-up. Source | Cevotec

Munich-based automation specialist Cevotec GmbH (Germany) presents its latest advances in robotic composite layup based on fiber patch placement (FPP) technology. Designed to bridge the gap between automated fiber placement (AFP) and manual layup, FPP expands the automation toolkit for composites manufacturers, especially in aerospace. It offers powerful options for fabricating geometrically complex components and processing diverse, tacky materials that typically challenge AFP systems. By enabling precise layup of plies and patches, FPP offers material, cycle time and cost savings of 20-60% compared to manual processes.

Cevotec is showcasing the new and advanced capabilities of its SAMBA Series FPP systems, including:

- A horizontal tailplane (HTP) fairing of a commercial aircraft, produced with FPP and demonstrating seven times increased improvement in layup time compared to the legacy process.

- A pressure vessel cut-out illustrating Cevotec’s dome reinforcement solution that won the 2024 CAMX Combined Strength Award.

- Fresh video footage from Cevotec’s lab, showcasing new layup features that address typical challenges for AFP on complex shapes.

As a highlight, the footage includes a demonstrator video featuring a double-curved barrel section with a steep 80° stepped edge — a challenge found at various aerospace components. The video illustrates how the SAMBA Pro system’s Post-Placement Push-In feature achieves uniform compaction and accurate fiber orientation around tight edges.

Furthermore, Cevotec’s expert for composites and FPP technology, Dr. Dimitrios Sikoutris, is holding a conference presentation on “Pressure Vessel Dome Reinforcements – Applied Design Exploration and Optimization,” scheduled on Wednesday, Sept. 10 at 10:00 a.m. in room W209 C. This educational session explores design considerations for FPP dome reinforcements.

The Cevotec team, including CEO Thorsten Groene and Dr. Dimitrios Sikoutris, are present all three days of the show.

Related Content

-

Mold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

-

Plyable releases AI-powered mold design tool

Plyable continues to rid composites engineers of workflow bottlenecks through an end-to-end automated system — from mold design to quotation to manufacturing fulfillment.

-

AI-powered robotic solutions support high-mix manufacturing

AI startup offers automation innovations for high-mix, high-variability, manual surface finishing applications.

Related Content

Mold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Read MorePlyable releases AI-powered mold design tool

Plyable continues to rid composites engineers of workflow bottlenecks through an end-to-end automated system — from mold design to quotation to manufacturing fulfillment.

Read MoreAI-powered robotic solutions support high-mix manufacturing

AI startup offers automation innovations for high-mix, high-variability, manual surface finishing applications.

Read MoreHow AI is improving composites operations and factory sustainability

Workforce pain points and various logistical challenges are putting operations resilience and flexibility to the test, but Industry 4.0 advancements could be the key to composites manufacturers’ transformation.

Read MoreRead Next

Artist Studio software update streamlines FPP design, programming

Cevotec releases enhancement for the design, robot programming and system performance of its composites software, helping users work more efficiently with fiber patch placement.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreComposites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read More