Film adhesive enables high-temperature bonding

CAMX 2024: Aeroadhere FAE-350-1, Park Aerospace’s curing modified epoxy, offers high toughness with elevated temperature performance when used in primary and secondary aerospace structures.

Share

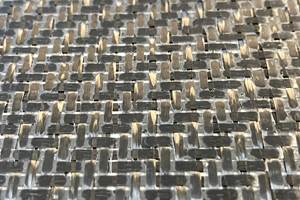

Source | Park Aerospace

Park Aerospace Corp. (Newton, Kan., U.S.) is featuring Aeroadhere FAE-350-1 film adhesive, the company’s novel 350°F curing modified epoxy designed for high-temperature bonding applications. FAE 350-1 is suited for service up to 350°F dry and 325°F wet. It offers optimized adhesion to composite, metal and honeycomb substrates.

Aeroadhere FAE-350-1 is offered in a variety of product forms, including mat and knit carriers. The film adhesive can be bonded directly, but only to composite substrates that have only peel-ply surface preparation. It has demonstrated high toughness and elevated temperature performance for use in primary and secondary aerospace structures, and is particularly suitable for aircraft nacelle and acoustic panel applications.

Aeroadhere has a material tack life of up to 20 days (certified for 18 days), and a mechanical life up to 40 days at room temperature. The adhesive has a shelf life of 365 days when stored at 0°F (-18°C) or below. Standard film weights are 0.03 PSF, 0.050 PSF, 0.09 PSF or 147 gsm, 244 gsm and 439 gsm.

Aeroadhere offers a flexible cure cycle from 280-350°F. A typical composite bond/metal bond autoclave cure cycle would be to heat up at 2-4°F/min to 350°F (177°C) for 120 minutes under 45 psi (3 bar). Multiple cure cycles at 350°F are possible. Park Aerospace recommends consulting the product’s technical data sheet for details related to cure cycles and adhesive properties.

Aeroadhere FAE-350-1 will be manufactured at Park’s new AS9100- and Nadcap-certified expansion facility on equipment employing novel manufacturing processes for film adhesives. The company’s facility with open capacity, and will include a product development lab with enhanced capability for testing adhesives.

Related Content

-

IPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

-

Innovations deliver improved composite bonding, sealing and structural reinforcement

JEC World 2025: L&L Products is exhibiting newly announced and proven technology solutions for composites fabricators, addressing core, adhesive and sealant needs.

-

Henkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

Related Content

IPSA acquires bonding adhesives based on MMA technology

IPS Adhesives (IPSA) introduces a line of adhesives using acrylate and MMA technology from L&L Products for the bonding of dissimilar materials such as metals and composites.

Read MoreInnovations deliver improved composite bonding, sealing and structural reinforcement

JEC World 2025: L&L Products is exhibiting newly announced and proven technology solutions for composites fabricators, addressing core, adhesive and sealant needs.

Read MoreHenkel releases digital tool for end-to-end product transparency

Quick and comprehensive carbon footprint reporting for about 58,000 of Henkel’s adhesives, sealants and functional coatings has been certified by TÜV Rheinland.

Read MorePontacol thermoplastic adhesive films are well-suited for composite preforms

Copolyester- and copolyamide-based adhesive films eliminate the need for sewing threads or binders when stacking laminates while improving the final part’s mechanical properties.

Read MoreRead Next

Park Aerospace is approved, qualified for facility production expansion

The aerospace company’s largest customer has approved an approximately 90,000-square-foot addition to Park’s Newton, Kansas, facilities for aircraft production programs.

Read MorePlant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More