Workforce Development

Pultruders need some self-control

Pultrusion veteran Joe Sumerak argues that in today’s more-competitive global marketplace, pultruders can no longer afford to overprice their products to compensate for process and supervision inefficiency.

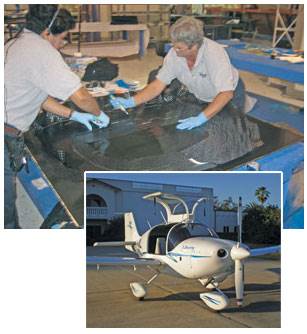

Read MoreFlying high on composite wings

FRP wings, fuselages and other primary and secondary structures on GA prop, turboprop and jet aircraft help lift this market to unprecedented heights.

Read MoreAutomate or emigrate

Automated fiber and tape placement is not just a notion, but a real manufacturing strategy, and one being embraced by HITCO Carbon Composites.

Read MoreIndustry Jobs: U.S. Army Research Laboratory

The Army Research Laboratory, Aberdeen Proving GD, MD is seeking qualifi ed candidates to lead a senior technical team to develop and transition advanced materials for armor ap- plications. Candidates with technical experience in material research, manufacturing science and dynamic behavior of materials are

Read MoreComposites Polycon 2007 Showcase

Tampa show attendance is up despite slow economy. ACMA reschedules 2008 show.

Read MoreComposites: Past, Present and Future: Marine Composites Training and Education, Part III

In Parts 1 and 2, Andre Cocquyt outlined the difficulty that composites manufacturers have faced in finding skilled employees and described a transferable model for local/regional training programs. In Part 3, he discusses the critical issue of program funding.

Read MoreRobotic trimming radically shortens Corvette fender production cycle

Plasan USA (Bennington, Vt.) molds the Chevrolet Z06 Corvette’s front fenders with hand layed, autoclave-cured carbon/epoxy prepreg. Until recently, however, manual deflashing, trimming and drilling of the demolded parts consumed more than an hour to meet requirements for edge quality and fastener hole location

Read MoreMarket Trends: The MRO challenge #x97; managing uncertainty

According to a recent report by Aerostrategy Management Consulting, spending by air transport maintenance and repair organizations (MROs) worldwide totaled $40.8 billion (USD) in 2006. Moreover, Aerostrategy (Ann Arbor, Mich. and Amersham, Buckinghamshire, U.K.) reports that spending on air transport maintenance

Read MoreRepair considerations

As more composite materials find a place on aircraft, boats, bridges and hundreds of other applications where part replacement is difficult and expensive, OEM engineers are considering the repairability of structural and secondary composite components during the initial design phase. According to a recent report by

Read MoreFuture composites engineers

To support the composites industry, an increasing number of colleges and universities offer composite materials and design courses within mechanical, chemical and civil engineering degree programs. Educators have networked progressively with suppliers and OEMs, cosponsoring projects that give students hands-on

Read More