Sheet Molding Compound

Q&A Forum: Automotive Composites

How will fiber-reinforced polymers fare in a post-recession, cost- and fuel-economy-obsessed auto market?

Read MoreSPE's ACCE 2010 Highlights

The Society of Plastics Engineers’ Automotive Composites Conference & Exhibition completed its first decade with a stellar slate of keynotes and papers.

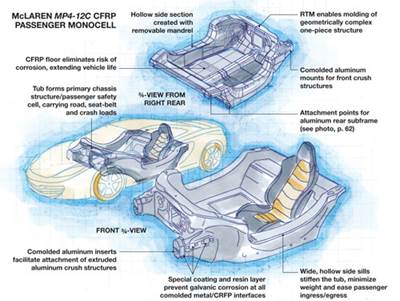

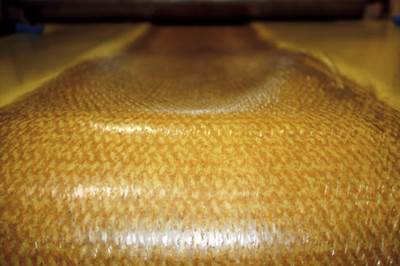

Read MoreF1-inspired MonoCell: Racing safety for the road

Resin transfer molding makes CFRP passenger cell mass-producible for new model supercar.

Read MoreJEC Composites 2010 Product Showcase

Although clouds of volcanic ash shut down postshow air traffic, the traffic on the show floor helped dispel the clouds of economic recession.

Read MoreComposites 2010 Product Showcase

The ACMA’s Las Vegas exhibition reflected an industry in recovery.

Read MoreReport from Detroit: NAIAS highlights

Electrics and hybrids make headlines, composites suppliers see hopeful signs after OEM restructuring.

Read MoreQuiet revolution: Composites in EVs

Startup automakers make use of composite body/chassis components to extend the range of hybrid-electric and battery-electric vehicles.

Read MoreCarbon Fiber: UP!

Despite 2008-2009 recession lows, prognosticators at ÂÌñÏ×ÆÞ's recent Carbon Fiber Conference predict a decade of highs.

Read MoreUBSs: Coming to North America

Common in Europe and Asia, the composite underbody shield might finally catch on in the U.S. and Canada.

Read MoreBio-based fillers: Reducing SMC mass

The Bio-Lite Technical Center of Excellence at the National Composites Center (Dayton, Ohio) is developing sheet molding compound (SMC) recipes capable of yielding finished parts with specific gravity as low as 1.2.

Read More