RTM

Turnkey manufacturing systems: Automated RTM for aerospace

German Aerospace Center’s (DLR) Center for Lightweight Production Technology site in Stade, Germany, has developed EVo, an automated production line capable of 100,000 complex composite parts/yr.

Read MoreTurnkey manufacturing systems: Materials, markets and maturation

Automated production cells promise affordability and less risk in scaling up composites production, but are they really the path forward?

Read MoreCW Ideas in Action

Ideas are just ideas until someone does the hard work of putting them into action and seeing results. CW's editors, therefore, inaugurate an annual review of Ideas in Action, celebrating a handful of hot concepts that could make those who conceived them "household names."

Read MoreReducing manufacturing cost via RTM

Airbus Bremen aims to replace dozens of prepreg components and assembly operations with a unitized multispar composite flap molded in a one-shot process.

Read MoreCMF project's process combines prepreg with RTM

Composite Multispar Flap (CMF) project at Airbus Bremen demonstrates SQRTM process for producing aircraft flaps

Read MoreCAMX 2015: Automotive, military innovations and on-floor demos

ACMA’s and SAMPE’s second combined event featured plenty of new products and thought-provoking conference sessions for the composites industry.

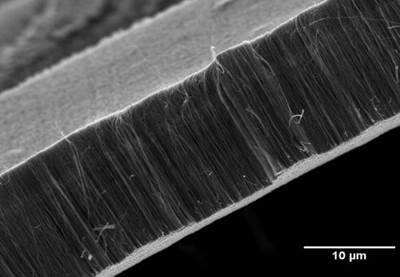

Read MoreThe end of delamination?

A spin-off from MIT's NECSTlab, N12 Technologies Inc. launches NanoStitch, the world's first vertically aligned CNT product via a continuous industrial process, which bridges adjacent CFRP plies, boosting interlaminar shear and increasing fatigue life by 100%.

Read MoreCytec gearing up for automotive expansion

With a new automotive-focused Application Centre set to open in December, Cytec Industrial Materials is emphasizing material and process flexibility to help OEMs integrate composites into forthcoming cars and trucks.

Read MoreSlideshow of SPE ACCE 2015

A look at the 15th edition of SPE’s Automotive Composites Conference & Exhibition (ACCE).

Read MoreSPE ACCE 2015 show report

Was this the year, finally, for the big break-through for automotive composites? Maybe, depending on to whom one talked or the presentation one heard.

Read More