Resins

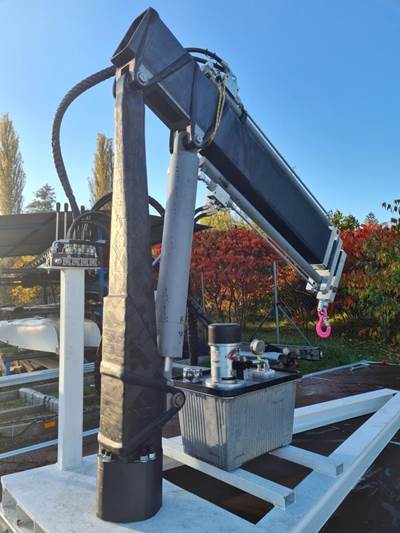

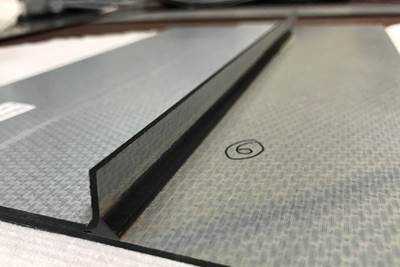

CompoTech, RTI collaborate on composite mast, telescopic boom for mobile cranes, davits

Cost-competitive carbon fiber-reinforced epoxy crane design uses CompoTech’s automated composites processes, eliminating welding or heat treatment and producing 50-70% stiffer structures.

Read MoreDLR develops additive WeldSealer process to seal joints, edges or modify surfaces

The robotic process developed for large components protects joints and edges, prevents cracks and allows multipart structures to be created as if cast in one piece.

Read MoreDemonstrating composite LH2 tanks for commercial aircraft

Toray Advanced Composites and NLR discuss the Netherlands consortium and its 4-year project to build demonstrator liquid hydrogen tanks, focusing on thermoset and thermoplastic composites.

Read MoreCFRTP upper stage propellant tank

PROCOMP uses in-situ consolidation AFP and ultrasonic welding to demonstrate lightweight, novel tank design.

Read MoreToray, Specialty Materials strengthen partnership for next-gen aerospace applications

Commercial partnership enables novel solution innovations with domestically produced, high-quality products within the U.S. supply chain.

Read More9T Labs, Purdue University to advance composites use in structural aerospace applications

Partnership defines new standard of accessibility to produce 3D-printed structural composite parts as easily as metal alternatives via Additive Fusion Technology, workflow tools.

Read MoreLanxess equips SUVs with Tepex dynalite underbody paneling

Robust thermoplastic panels are 30% lighter than steel designs, features higher resistance to stone impacts or other damage, indicating future applications in electric-, hydrogen-powered vehicles.

Read MoreCollins Aerospace selected by AFRL to build thermoplastic composite fin for F-16

Part of $100 million, five-year investment to advance, qualify thermoplastic composites for military and commercial aero applications.

Read MoreCDZ Compositi introduces patented 3D Flex Composite

Specialist in structural and aesthetic prepreg press parts enhances 3D shaping and flexibility in composite parts using carbon and other reinforcement fibers.

WatchForvia brand Faurecia exhibits XL CGH2 tank, cryogenic LH2 storage solution for heavy-duty trucks

Part of its full hydrogen solutions portfolio at IAA Transportation 2022, Faurecia also highlighted sustainable thermoplastic tanks and smart tanks for better safety via structural integrity monitoring.

Read More