Processes

PEEKSense high-temperature thermocouple for PEEK composites curing

TE Wire & Cable’s PEEKSense thermocouple sensor is a high-temperature autoclave thermocouple assembly for polyetheretherketone (PEEK) composite applications.

Read More3D Platform large-format 3D printers

3D Platform has introduced two platforms for 3D printing: the WorkCell and the larger WorkCenter 500.

Read MoreFAMACOM project to develop more efficient manufacturing process for aerospace parts

The Spanish consortium, led by Aerotecnic, is using microwave curing for manufacturing large sandwich-structured composite parts.

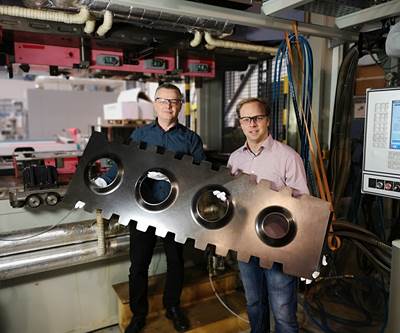

Read MoreBig additive machines tackle large molds

In commercial aerocomposites fabrication, molds reign supreme, but they are expensive. Large-format additive manufacturing systems are poised to make production-ready molds quickly and affordably.

Read MoreAutomated, in-situ inspection a necessity for next-gen aerospace

Inline inspection technologies continue to evolve with the aim of providing faster and more accurate part inspection.

Read MoreOptima 3D launches next-generation 3D weaving machines for composites

Digital control and innovative shuttle system enable rapid parameter and sequence change for net shape preforms, billets, para beams and more.

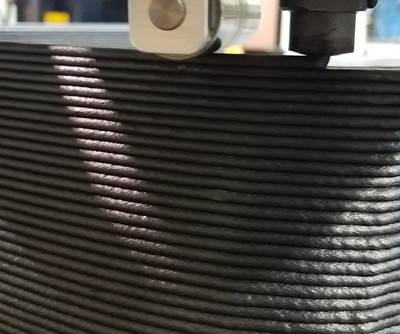

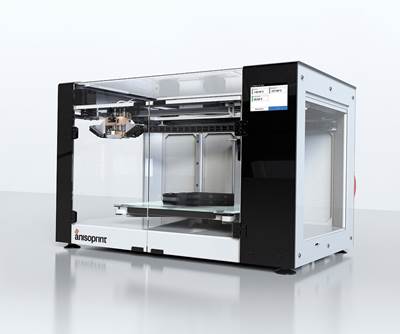

Read MoreAnisoprint launches basalt fiber for continuous-fiber 3D printing

The material is said to be 15 times stronger than plastic, five times lighter than steel and 1.5 times stronger and lighter than aluminum.

Read MoreSpirit AeroSystems invests in qualification program with Toray prepreg

The world’s largest aerospace tier supplier seizes the opportunity to develop its own allowables for a carbon fiber prepreg, setting an important precedent.

Read MoreHP-RTM for serial production of cost-effective CFRP aerostructures

Merging automotive process and tooling with aerospace quality to meet increasing production rates.

Read MoreLarge, high-volume, infused composite structures on the aerospace horizon

Infused carbon fiber composite structures are not new, but they have never been built at the rates anticipated for next-generation, single-aisle aircraft. It is a daunting prospect — but a feasible one.

Read More