Anisoprint launches basalt fiber for continuous-fiber 3D printing

The material is said to be 15 times stronger than plastic, five times lighter than steel and 1.5 times stronger and lighter than aluminum.

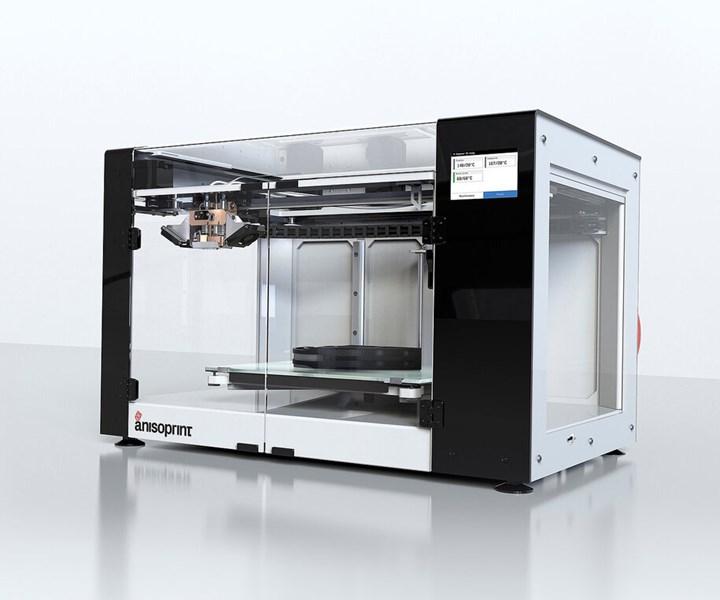

Anisoprint’s basalt fiber composite is available for use with its Composer continuous-fiber 3D printer. Source | Anisoprint

Anisoprint (Esch-sur-Alzette, Luxembourg), a manufacturer of continuous carbon fiber 3D printers and materials, recently launched a basalt fiber composite for use with its 3D printing technology.

According to the company, the material, when applied to its 3D printing technology, is 15 times stronger than plastic, five times lighter than steel, and 1.5 times stronger and lighter than aluminum. It also is said to significantly decreases manufacturing costs.

Since basalt fiber also features radio transparency, Anisoprint says that parts made of its basalt fiber composite do not significantly alter the amplitude and phase of radio-frequency electromagnetic waves transmitted through them, making it an ideal option for non-conductive elements and isolators.

Anisoprint’s technology involves continuous composite fiber coextrusion with thermoplastic polymers and enables variations in fiber direction, volume ratio and material density.

Related Content

-

NCC receives investment to support next-gen composite wing

The NCC was awarded a £15.8 million U.K. government grant for HRMCap to de-risk, accelerate innovation in high-rate large aerocomposites structure manufacturing.

-

Sinonus launches energy-storing carbon fiber

Swedish deep-tech startup Sinonus is launching an energy-storing composite material to produce efficient structural batteries, IoT devices, drones, computers, larger vehicles and airplanes.

-

CIRA qualifies CMC structures for the reusable Space Rider

Italian team designs, builds and tests multiple large, complex thermal protection system structures made from patented ISiComp C/C-SiC ceramic matrix composites.

.jpg;width=70;height=70;mode=crop)