Machining/Drilling

Composite repair: Lessons learned, challenges and opportunities, Part I

As aerospace companies look to increase the scope and quality of repairs, through standardized training and increased automation, their lessons learned (outlined here in Part 1 of a two-part examination) can smooth the repair path for other industries.

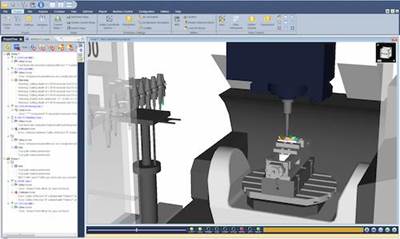

Read MoreCGTech to feature VERICUT Version 8 at IMTS

VERICUT V8 features a new ribbon bar allowing the user to quickly select the required function.

Read MoreClear Carbon & Components: Bristol, RI, US

Breaking barriers in process and complexity, this agile manufacturer is gaining renown as a composites problem solver and champion of Class A cosmetic surfaces.

Read MoreCFRP: Opportunities in orthopedics

Carbon fiber has a niche, but can it secure a larger piece of a high-growth pie?

Read MoreAircraft composites repair: Plasma’s potential for better bonds

Plasma treatment might be a key enabling technology in the pursuit of certification-worthy, fastener-free adhesively bonded repair patches applied to aircraft primary structure.

Read MoreJEC World 2016 exhibition and product previews

JEC World 2016 will be held in Paris March 8-10. These are some of the products that will be found at the show.

Read MoreAircraft composites repair moves toward maturity

New technologies seek to address the challenges MROs will increasingly face in the age of commercial airliners with composite airframes.

Read MoreTerma Aerostructures: Grenaa, Denmark

This Danish manufacturer of precision composite aircraft parts and components has emerged as a significant player in fabrication of Lockheed Martin’s F-35 Lightning II.

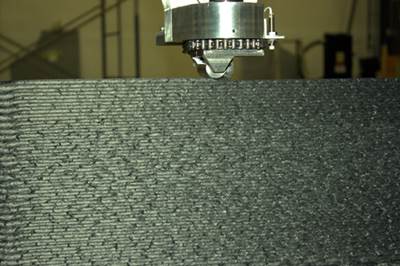

Read MoreThermwood developing large-scale additive manufacturing system

The large-format additive manufacturing machine will produce near net shape parts up to 10 by 10 by 5 ft and provide post-process machining and trimming functions as well.

Read More