Compression Molding

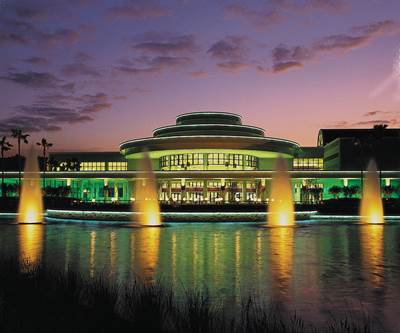

IACMI officially opens new innovation facility in Detroit

Two years in the works, the IACMI Vehicles Scale-Up Facility offers the automotive industry a composite materials and manufacturing development innovation center.

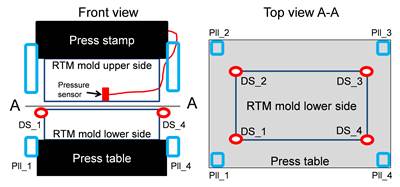

Read MoreFraunhofer ICT in-mold pressure sensors for HP-RTM

Pressure sensor-based mold fill expected to maximize part consistency and minimize cycle time for auto industry molders.

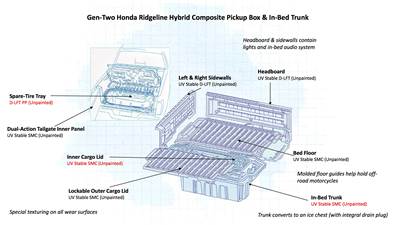

Read MoreSMC + D-LFT: A hybrid box for the Gen 2 Ridgeline

D-LFT optimizes vertical component functionality while first use of weatherable SMC eliminates paint, reduces mass and stands up to tough-duty use.

Read MoreCAMX 2017 show preview

At North America’s premier composites conference and exhibition, the business at hand is definitely not business as usual.

Read MoreCAMX 2017 preview: Siempelkamp

Composites machinery specialist Siempelkamp (Krefeld, Germany) is featuring its compression equipment for sheet molding compound (SMC), phase change material (PCM), resin transfer molding (RTM) and thermoplast forming.

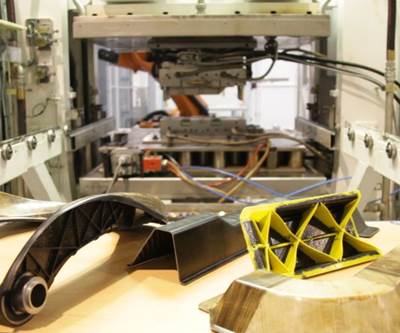

Read MoreCAMX 2017 preview: OEM Press Systems

OEM Press Systems (Fullerton, CA, US), a manufacturer of hydraulic presses, is featuring its robotic mold-handling systems, designed to reduce process cycle time and eliminate the lifting of molds by an operator.

Read MoreA look inside Fraunhofer ICT

Fraunhofer-Gesellschaft (Munich, Germany) is the largest applied research organization in Europe, with more than 67 institutes and research units located throughout Germany staffed by 24,500 people, mostly scientists and engineers. CW recently got a chance to tour one, Fraunhofer ICT in Pfintzal, Germany.

Read MoreSMC: Old dog, more tricks

In the sheet molding compound renaissance, the advent of new resins and compounds are broadening the definition and application of this versatile family of composites.

Read MoreCenter for mass production of lightweight composites

German R&D center brings together 8 institutes and more than 80 companies from 120 countries to help industrialize composite parts production.

WatchAutomated Preforming, Part 3: Quilted Stratum Process

CW’s tour of Cetim and the QSP line which preforms multi-thickness thermoplastic materials in 40-90 seconds for composite parts with cycle times of 1-2 minutes.

Watch