Compression Molding

Century Tool expands compression molding capability to include bathtubs, spas

Century Tool and Gage will now offer compression molds for bathtubs, showers, spas and other large composite structures for the home.

Read MoreFiberject process achieves 3D thermoplastic cosmetic carbon parts

Mubea Carbo Tech develops manufacturing of complex-shaped, fully integrated and high-accuracy cosmetic CFRP components for high volumes using a thermoplastic matrix.

Read MoreComposites One and IACMI to host two-day workshop

The workshop, called “the Evolution of Composites,” will be held March 20-21 at Vanderbilt University in Nashville, Tenn., U.S.

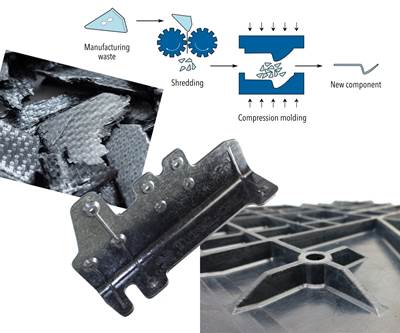

Read MoreRecycled thermoplastic composites for production

Multi-year R&D at ThermoPlastic composites Applications Center (TPAC), TenCate and Clean Sky 2 demonstrate economic advantage of serial production using recycled materials.

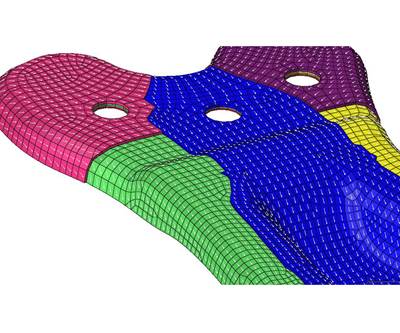

Read MoreDesign engineering of tailored preforms

Tailored preforming has opened new doors in composites fabrication, but designing for it requires tools that understand and work with this complex process.

Read MoreJEC World 2019 preview: Wabash MPI and Carver

Wabash MPI and Carver Inc. (Wabash, Ind., U.S., 6/R51) are highlighting their lines of hydraulic and pneumatic presses for the composites industry.

Read MoreJEC World 2019 preview: Hexcel

Hexcel (Stamford, Conn., U.S.) is featuring range of composite innovations for customer applications in aerospace, automotive, energy and marine markets.

Read MoreThermoplastic overmolded thermosets, 2-minute cycle, one cell

Adhesive-free, functionalized hybrid composites enabled by industry-first, integrated molding cell.

Read MoreRucks Maschinenbau introduces continuous compression molding system for organosheets

The company claims this process offers a lower-cost option for the manufacture of organic sheets, while enabling higher pressing forces and temperatures.

Read MoreFACC receives STC approval for its Passenger Luggage Space Upgrade program

The glass fiber-reinforced composite overhead stowage bins are said to increase space while reducing weight by up to 67 percent.

Read More