Additive Manufacturing

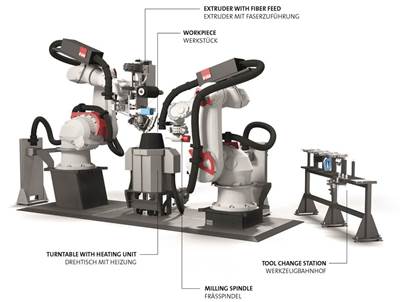

Fill ACCUBOT combines extrusion with continuous fiber additive capabilities

The system’s additive capability, augmented by subtraction via integrated robotic milling creates the potential for the production of cost-effective, high-performance and multifunctional composite components.

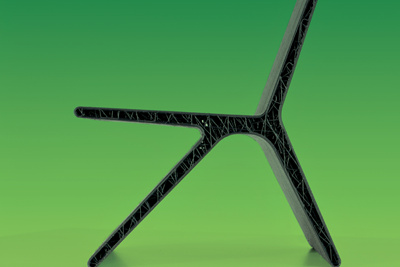

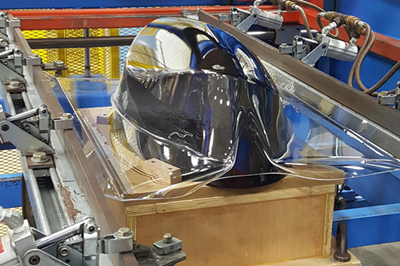

Read MoreMAMBO tests the waters for 3D printing large marine structures

With its MAMBO boat, Moi Composites demonstrates use of its continuous fiber 3D printing technology for customized, automated production for the boating industry.

Read MoreCEAD and Belotti make large-scale additive composites manufacturing accessible for industry

Strategic partnership combines expertise of additive and subtractive manufacturing into single hybrid solution: BEAD.

Read MoreOhio State CDME advances AM technology with Cincinnati Inc. MAAM printer

With an additive machine that prints ULTEM, PEEK and PEKK thermoplastics, university researchers and students expect to take 3D printing to new heights, including printing a fully functional turbine and internal combustion engines.

Read MoreCovestro introduces 3D printing material made from recycled PET

Glass fiber-filled rPET suitable for high performance and structural applications using 3D pellet printing/fused granulate fabrication (FGF).

Read MoreContinuous Composites, Saint-Gobain collaboration advances CF3D technology

Saint-Gobain to bring CF3D production systems in-house, with a focus on certifying the patented technology for use in commercial aerospace applications.

Read MoreHexagon, Authentise end-to-end software platform streamlines AM workflow

Solution integrates shop floor data with data intelligence to orchestrate consistent quality through concept to part for AM industrialization.

Read MoreExOne acquisition accelerates expansion into 3D-printed tooling for composites

Patented 3D-printed sand tooling solution from Freshmade 3D applicable for composite layup, vacuum forming, compression molds, with 30-50% cost savings and design flexibility.

Read MoreThermwood expands LSAM product line availability

Large dual gantry print and trim machines for 3D-printed thermoplastic composites offered in 15-foot width model, with wider gantry design and range of print core, print head options.

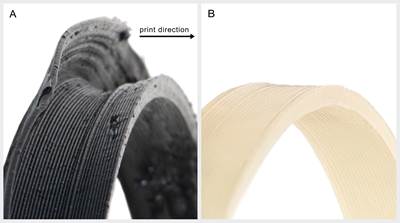

Read MoreNatureWorks Ingeo 3D700 biopolymer reduces LSAM warpage, minimizes print failures

Testing by NatureWorks’ global partners demonstrates a shrink rate less than 0.25% in printed parts and obtainable lower print temperatures due to optimized melt viscosity and microstructure.

Read More