Additive Manufacturing

U.S. DOE announces $30 million wind turbine materials, manufacturing funding opportunity

Funding opportunity seeks to increase cost efficiency of wind power generation through R&D projects for lightweight composite materials, streamlined 3D printing processes.

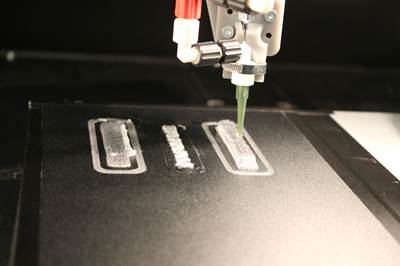

Read MoreNovel 3D printing process achieves development of bio-based composite components

Modeling nature’s material processing techniques, research at DITF and Arburg has enabled the printing of cellulose continuous fibers reinforced with a cellulose matrix at ambient temperatures.

Read MoreOptimizing a thermoplastic composite helicopter door hinge

9T Labs used Additive Fusion Technology to iterate CFRTP designs, fully exploit continuous fiber printing and outperform stainless steel and black metal designs in failure load and weight.

WatchWeber State applies composite-based 3D printing for aerospace support, research

The Utah-based university’s recently upgraded MARS Center installed an Impossible Objects CBAM printer to engage in projects with DOD and DOE potential.

Read MoreLarge-format 3D printing enables toolless, rapid production for AUVs

Dive Technologies started by 3D printing prototypes of its composite autonomous underwater vehicles, but AM became the solution for customizable, toolless production.

WatchHigh-temperature composite 3D printing facilitates design, manufacture of deployable space structures

Opterus R&D employs an AON3D printer and OOA prepregs to build the tooling, prototypes and end-use versions of its foldable CFRP satellite structures.

WatchMetal AM advances in composite tooling, Part 2

Toolmakers and molders continue to realize the benefits of additive versus conventional/subtractive manufacturing of molds and mold components.

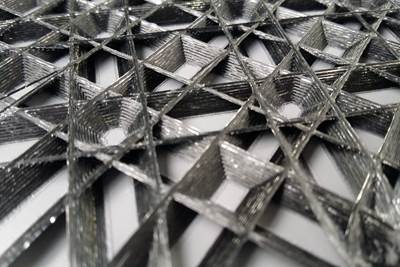

Read MoreDrawing design cues from nature: Designing for biomimetic composites, Part 2

As biomimetic design continues to inform composites manufacturing, technologies like 3D printing, tailored fiber placement, braiding and filament winding prove strong candidates for making these structures a reality.

Read MoreKimya features Kimya PC-FR 3D filament for the transportation sector

Flame-retardant polycarbonate filament reaches EN45545 certification and meets REACH and RoHS standards for production of parts in railway, automotive, electronics.

Read MoreSeaBioComp project develops biocomposite demonstrator products for marine applications

Prototype products explore thermoplastic polymers, natural fibers and 3D printing technologies to effectively reduce the use of fossil-based materials in the marine sector.

Read More