Search Results

Showing 81 – 90 of 2863 results

Filament winding is a specialized technique used in composite manufacturing, involving the precise and automated winding of continuous fibers onto a rotating mandrel or mold. This method allows for the creation of strong and seamless structures, optimizing the alignment and orientation of the fibers to meet specific design requirements. Filament winding is employed in producing cylindrical or conical composite parts, such as pipes, pressure vessels, and aerospace components, enabling engineers to tailor the strength, stiffness, and performance characteristics of the final product.

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

The wind energy market has long been considered the world’s largest market, by volume, for glass fiber-reinforced polymer (GFRP) composites — and increasingly, carbon fiber composites — as larger turbines and longer wind blades are developed, requiring higher performance, lighter weight materials. The outer skins of wind and tidal turbine blades generally comprise infused, GFRP laminates sandwiching foam core. Inside the blade, rib-like shear webs bonded to spar caps reinforce the structure. Spar caps are often made from GFRP or, as blade lengths lengthen, pultruded carbon fiber for additional strength.

Production commencement on Iowa line is intended to recover and divert 30,000 tons of scrapped materials from wind blades each year.

Real-world demonstrations in the U.K. will prove the Artemis EF-24 CTVs capability to operate safely under extreme wind and tide conditions for wind farm operators.

Several new sources say that Siemens has told customers its largest wind turbine yet may be introduced by the end of the decade.

Earnings results indicate the wind blade manufacturers’ strategic decisions to optimize its manufacturing footprint and streamline operations, positioning it more strongly headed into 2025.

Fourth commercial-scale wind farm off of Rhode Island joins Vineyard Wind, South Fork Wind and Ocean Wind 1 projects, brings U.S. construction pipeline to 2.7 GW.

LATW and tape winding machine enhances TITK Rudolstadt’s ability to conduct advanced thermoplastic R&D projects, particularly for aerospace.

Delivery of the single-spindle robotic setup with an ATP head will advance the R&D organization’s work in CUBIC, GENEX and Carbo4power initiatives targeting sustainable composites development.

U-Ming Transport’s Grand Pioneer VLOC vessel is expected to save an average 10-12% fuel emissions during deep-sea service between Brazil and China.

Multi-year agreement between the joint venture and a South Asian wind turbine manufacturer contributes to composite spar cap development.

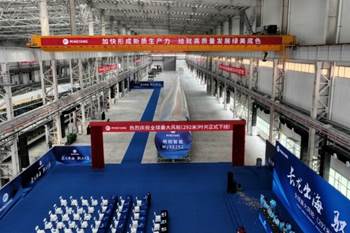

First MySE292 offshore wind blade from MingYang Group successfully rolled off the production line in February.