Search Results

Showing 411 – 420 of 777 results

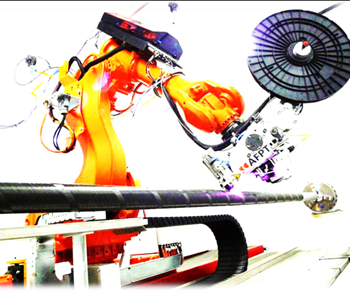

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

Bonding and welding play vital roles in the assembly and fabrication of composite materials, offering methods to join components together effectively. Bonding involves the use of adhesives or bonding agents to create strong connections between different composite parts or between composites and other materials. Adhesives provide uniform stress distribution, enabling lightweight and durable structures. On the other hand, welding techniques like ultrasonic welding or induction welding are employed specifically in thermoplastic composites, where heat is used to melt and fuse the materials together.

In the Aftermarket category, the winner was the carbon fiber composite spoiler on the 2016 Chevrolet Corvette sports cars.

€600,000 European grant awarded to croatian maritime research company to develop ship repair techniques using composite materials.

Rapidly built emergency hospital wards built in response to the coronavirus outbreak incorporate AOC resins in a pre-fabricated roofing system.

ATSP Innovations Inc. is exhibiting its full line of high-temperature resins at CAMX 2019, as well as its Self-Bond adhesive process.

Clean Sky 2 SAT-AM project targets 4-hour, door-to-door mobility and reduced manufacturing, maintenance costs for 4-19 passenger, Small Air Transport.

Using the new automated manufacturing process, the company aims to expand its current thermoplastics product range with an eye toward mass production.

LANXESS extends plastic-metal hybrids to tubular structures.

Solvay Composite Materials has developed FusePly, an epoxy-based film that is designed to co-cure with a prepreg and provide a chemically active surface that reacts with functional groups in adhesives to create a covalently bonded structure.

FITS Air and FITS Base sandwich panels provide alternative material avenues for aerospace and other industries, including low weight, low part production cost, thermoformability and recyclability.

According to BTG Labs, common surface treatment methods like abrasion and plasma treatment work best for different materials.