Search Results

Showing 351 – 360 of 777 results

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

Bonding and welding play vital roles in the assembly and fabrication of composite materials, offering methods to join components together effectively. Bonding involves the use of adhesives or bonding agents to create strong connections between different composite parts or between composites and other materials. Adhesives provide uniform stress distribution, enabling lightweight and durable structures. On the other hand, welding techniques like ultrasonic welding or induction welding are employed specifically in thermoplastic composites, where heat is used to melt and fuse the materials together.

New material for Cincinnati Inc.’s Small Area Additive Manufacturing system (SAAM) is designed for custom tooling and fixture applications

Developed for mass transportation applications, including aircraft interiors, the material improves upon the cost, sustainability and versatility of conventional sandwich layup.

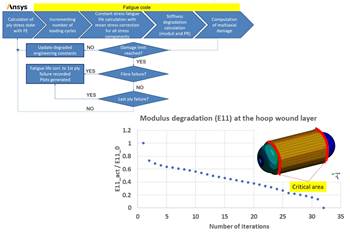

To aid design of fatigue-resistant structures, Econ Engineering has developed an algorithm to evaluate ply-based cyclic stiffness degradation combined with an FE failure check, validated for a CF/PAEK pressure vessel.

The Orion crew module capsule is for NASA Exploration Mission-2 (EM-2), which is designed to return astronauts to the moon, and beyond.

Magna received three first-place awards at the 2018 Society of Plastics Engineers Automotive Awards gala in recognition of its lightweighting efforts enabled by advanced materials.

Film and paste adhesives, wet peel-ply and potting compounds enable the aviation industry to utilize advanced materials that contribute to lightweighting, more efficient designs, and improved sustainability.

Gummiwerk KRAIBURG’s elastomer product protects against impact, directly adheres to materials, improves damping properties and more.

Adhesive-free, functionalized hybrid composites enabled by industry-first, integrated molding cell.

The highest-performing facilities from the 2022 CW Top Shops benchmarking survey share insights about business growth, overcoming labor shortages, sustainability best practices and more.

Hypertherm has launched Robotmaster V7, a task-based robot programming platform rebuilt on new architecture to offer integrated CAD/CAM functionality and more intuitive robot programming tools.