Search Results

Showing 331 – 340 of 777 results

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

Bonding and welding play vital roles in the assembly and fabrication of composite materials, offering methods to join components together effectively. Bonding involves the use of adhesives or bonding agents to create strong connections between different composite parts or between composites and other materials. Adhesives provide uniform stress distribution, enabling lightweight and durable structures. On the other hand, welding techniques like ultrasonic welding or induction welding are employed specifically in thermoplastic composites, where heat is used to melt and fuse the materials together.

Tantec is featuring its full line of plasma treatment systems, with specific emphasis on PlasmaTEC-X, the newest product in the company’s atmospheric plasma treatment line.

Distributor Techsil (Bidford-on-Avon, UK) has introduced a new light-curing adhesive called Vitralit UV 4802, for bonding high-temperature-resistant thermoplastics such as PEEK with other non-compatible materials.

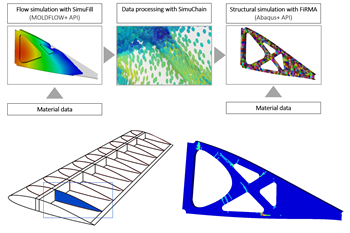

Simutence and Engenuity demonstrate a virtual process chain enabling evaluation of process-induced fiber orientations for improved structural simulation and failure load prediction of a composite wing rib.

Composite and hybrid components reduce mass, increase functionality on electric and conventional passenger vehicles.

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

The system combines a tape-laying cell with a consolidation unit to produce fit-for-purpose blanks with 15-30 tapes in 1-minute intervals.

The components were manufactured for Bell by GKN Aerospace for the V-280 Valor tiltrotor.

The machine is designed for high-precision cutting of fiber reinforcements for a variety of end market applications.

Eight category winners, the Hall of Fame award and the Vehicle Engineering Team Award and Lifetime Achievement Award winners were revealed at the Nov. 8 event.

Based in the Nantes, France region, the Shap’in TechCenter combines R&D and a production plant within a single facility, capitalizing on Daher’s composites expertise.