Search Results

Showing 11 – 20 of 780 results

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

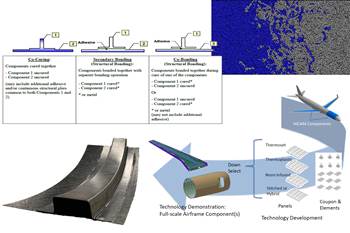

Bonding and welding play vital roles in the assembly and fabrication of composite materials, offering methods to join components together effectively. Bonding involves the use of adhesives or bonding agents to create strong connections between different composite parts or between composites and other materials. Adhesives provide uniform stress distribution, enabling lightweight and durable structures. On the other hand, welding techniques like ultrasonic welding or induction welding are employed specifically in thermoplastic composites, where heat is used to melt and fuse the materials together.

FAUSST technology enables fast, reliably welded connection of metal components in composite structures.

Ultrasonic joining has been used for decades, but is now being advanced to enable smart, automated fastening in composites and multi-material assemblies.

Two years after its launch, Daher’s technology center has been actively pursuing its ambitions to mature aerocomposites, from thermoplastics welding to rethinking their entire life cycle.

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

EU-founded project is supporting composite technology advancement for aerospace via automated manufacturing, integrated sensing, novel composite materials development and digital transformation.

Fraunhofer IFAM and partners have completed left and right welds connecting the upper and lower fuselage halves and sent the 8×4-meter full-scale section to ZAL for integration with a cabin crown module and testing.

Netherlands consortium advances cryogenic composites testing, tank designs and manufacturing including AFP, hybrid winding, welding of tank components and integrated SHM and H2 sensors for demonstrators in 2025.

Multiple methods advance toward faster robotic welds using new technology for increased volumes and larger aerostructures.

Multiple demonstrators help various welding technologies approach TRL 6 in the quest for lighter weight, lower cost.

More widespread use of welded composite structures within a decade? Yes, but further developments are needed.