Search Results

Showing 141 – 150 of 777 results

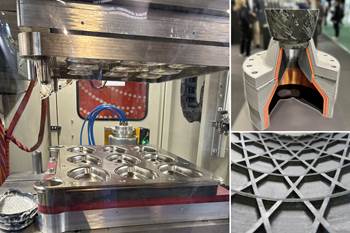

Processes in composites manufacturing encompass a diverse array of techniques employed to fabricate composite materials. These processes include methods like hand layup, where layers of resin and reinforcement materials are manually placed, and vacuum infusion, where a vacuum draws resin into a preform. Other techniques like compression molding, filament winding, and automated methods such as 3D printing are utilized to create intricate and specialized composite structures. Each process offers unique advantages in terms of precision, scalability, and efficiency, catering to diverse industry needs. As technology advances, newer methods are emerging, promising faster production cycles, reduced waste, and increased customization, driving the evolution of composite manufacturing towards more sophisticated and versatile methodologies.

Bonding and welding play vital roles in the assembly and fabrication of composite materials, offering methods to join components together effectively. Bonding involves the use of adhesives or bonding agents to create strong connections between different composite parts or between composites and other materials. Adhesives provide uniform stress distribution, enabling lightweight and durable structures. On the other hand, welding techniques like ultrasonic welding or induction welding are employed specifically in thermoplastic composites, where heat is used to melt and fuse the materials together.

The following companies, organizations and project consortia featured strong collective innovation concepts, to be on display at JEC World 2025 in March.

CW senior technical editor Ginger Gardiner discusses some of the developments and demonstrators shown at the industry’s largest composites exhibition and conference.

Joint technology breaks barriers to bonding lightweight flexible solar panels to roofing structures made from aluminum, coated steel and composites.

These 33 finalists, celebrating successful projects and partnerships in composites innovation, will be narrowed down to 11 winners at the JEC World 2025 Premiere on Jan. 13, 2025.

Incorporation of FiberForm advances NIAR ability to convert metallic components to fiber-reinforced thermoplastic versions in cargo aircraft.

New tests, analysis enable databases, models, design guidelines and methodologies, combining materials science with production processes to predict and optimize part performance at temperatures above Tg (≈150-180°C) for wing and engine structures.

CAMX 2023: Rotaloc bonding fasteners come in a variety of baseplate styles, threads, sizes and materials for high-strength, nondestructive bonding with fiber-reinforced composites and thermoset/thermoformed plastics.

CDCQ, LxSim, Addcomp and Argon 18 collaborate to optimize a carbon fiber/PA6 bike seat post, democratizing AFP and demonstrating materials and process for future designs and production.

Lehvoss’ carbon fiber-reinforced thermoplastic composite materials are being used in the production of an e-bike set that will taken an expedition across North Africa.

CW editor-in-chief Scott Francis reflects on the ways in which the composites industry has changed and also stayed the same based on observations from this year’s JEC World.