Thermwood advances LSAM capabilities with automatic print temperature monitoring

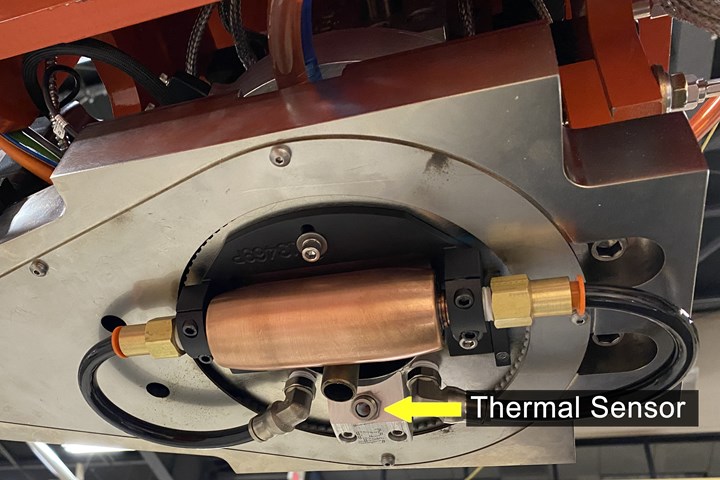

Thermal Sensor Layer Automation system uses a non-contact temperature sensor for continuous temperature data, ensuring precise fusion between large-scale thermoplastic printed layers.

All photo credit: Thermwood Corp.

Thermwood Corp. (Dale, Ind., U.S.) has unveiled a new large-scale additive manufacturing (LSAM) technical capability, the Thermal Sensor Layer Automation system, which is said to automatically monitors print temperature, and ensures complete and precise fusion between large-scale thermoplastic printed layers no matter the application.

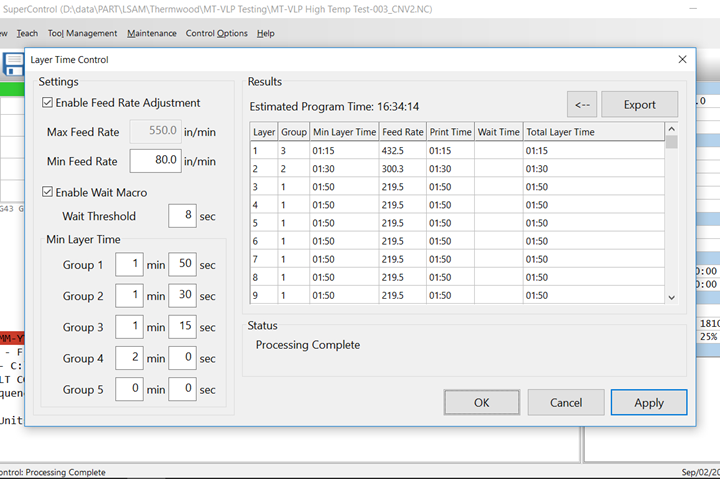

The integrated system continuously measures the temperature of a printed layer just before a new bead is added, which enables the printer to automatically regulate the feed speed, using the “Layer Time Control” option. With this adjustment, says the company, the printing process would be very close to, the ideal temperature needed to achieve the best possible layer-to-layer fusion for a high-quality printed part.

The new process uses a noncontact temperature sensor which rotate about the print nozzle under servo control and continuously measures the temperature of the existing layer less than a half inch in front of the moving print nozzle. This is said to provide precise feedback of the temperature at the moment of layer fusion, ensuring integrity of the bond being generated at every point on every layer.

Data from the probe is then processed through an advanced algorithm which adjusts the speed at which each layer is printed. The algorithm takes into account the temperature at the point of printing compared to the target temperature, as well as the changing geometry of the part as it grows. Print speed is no longer defined in the print CNC program but is continuously adjusted by the LSAM control system itself during printing, in response to changes in the print environment.

Layer Time Control feature.

According to Thermwood, with this system, optimum print temperature is now part of the parameters stored in the control for each polymer and is determined when the polymer is first qualified. To run a specific material using a properly equipped LSAM, it is only necessary to load a part program, specify the material and turn it on. The entire build process, including all temperature control, is automated. Further, the system is said to achieve much tighter control of the basic print process.

Temperature data from the print process is made available in several forms, including digital readout displays, real time, the current temperature reading as well as the average temperature for the layer being printed. When the print is complete, a report is available that details the print temperature profile of each printed layer.

Thermwood adds that for the first time in extruder-based LSAM, the temperature at the moment of layer fusion can be measured and controlled, opening the possibility for more advanced research focused on the core of an extruder-based print process.

Existing LSAM customers can upgrade their current systems to the Thermal Sensor Layer Automation System in the field by contacting Thermwood’s Retrofit department.

Related Content

-

SAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.

-

Zünd, Loop Technology partner on FibreLine preforming system

Pairing Loop Technology’s automation with Zünd digital cutters provides faster cutting, less stray fibers, higher ply accuracy and more precise preforms for composite aerostructure manufacturing.

-

Mold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.