Molecular Plasma Group introduces automated technology for adhesion promotion

MolecularGRIP combines atmospheric plasma treatment with adhesion promoter chemistry for automated, environmentally-friendly adhesion promotion on material surfaces.

’s (MPG, Foetz, Luxembourg) automated, solvent-free MolecularGRIP technology has been developed to promote better adhesion on inert and sensitive part surfaces. Said to be effective on a variety of material surfaces, including carbon fiber and natural fiber composites, as well as polyolefins, fluorinated polymers and metals, the one-step MolecularGRIP process combines plasma treatment with MPG’s adhesion promoter chemistry. The plasma activates both the part surface and the coating molecules, which covalently bind onto the surface.

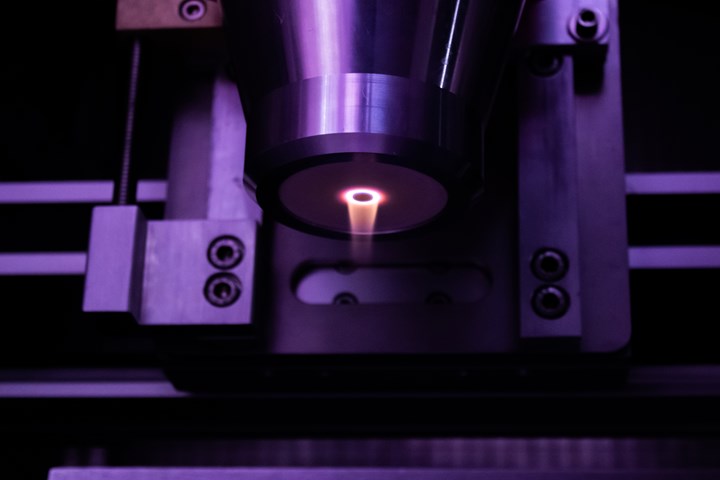

MPG’s PlasmaLine system.

The technology is customizable with a range of plasma gases and organic chemicals to work with a variety of sensitive and inert materials to achieve superior bonding. MolecularGRIP can be used with either MPG’s PlasmaSpot or PlasmaLine systems.

According to MPG, the process is both environmentally friendly — requiring relatively little energy, few chemicals and near zero emissions — and is easily scalable in a robust, industrial process. In addition, to meeting a range of customer needs, the company offers proven application development services, off-the-shelf R&D equipment, leasing and rental options and customized industrial solutions.

Related Content

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

The next evolution in AFP

Automated fiber placement develops into more compact, flexible, modular and digitized systems with multi-material and process capabilities.

-

Active core molding: A new way to make composite parts

Koridion expandable material is combined with induction-heated molds to make high-quality, complex-shaped parts in minutes with 40% less material and 90% less energy, unlocking new possibilities in design and production.

.jpg;width=70;height=70;mode=crop)