CAMX 2019 exhibit preview: SurfEllent

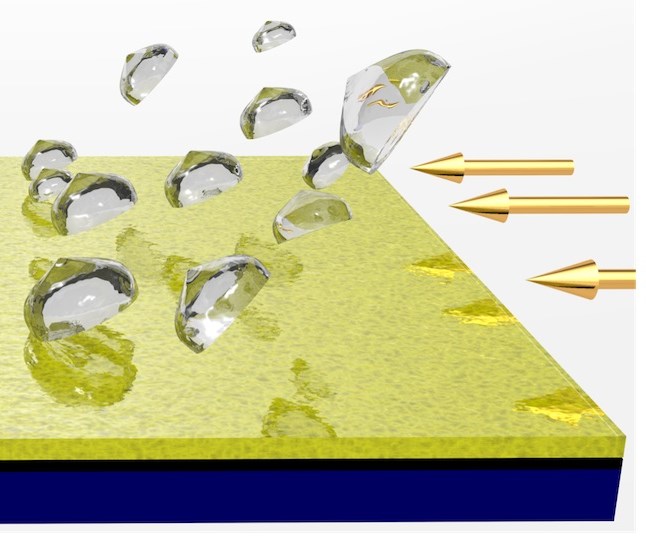

SurfEllent is featuring its anti-icing coatings, which are designed for high mechanical, chemical and environmental durability at a low cost.

Source | SurfEllent

SurfEllent (Houston, Texas, U.S.) is featuring its anti-icing coatings, which are designed for high mechanical, chemical and environmental durability at a low cost.

According to the company, anti-icing plays a critical role in protecting infrastructures, transportation, energy systems, and aircraft turbomachinery against the detrimental effects of icing. Despite the importance of anti-icing, the company says most coatings are ineffective for ice repellency and long-term durability.

SurfEllent's anti-icing coating technology is in the form of a liquid that reportedly can be applied to any surface, including polymers and ceramics. The liquid material can be packed in both cans and spray bottles depending on the desired end-use. The liquid coating in cans is applied through brushing, while the spray form is directly applied to a surface. Once applied on the surface, the liquid is said to cure in less than an hour, forming a solid and highly durable coating.

Related Content

-

Airbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

-

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

-

Trends fueling the composites recycling movement

Various recycling methods are being considered for composites, from novel dismantling and processing, to building capacity and demonstrating secondary use applications.

.jpg;width=70;height=70;mode=crop)