Brown Machine BMG AR platform offers secure thermoforming data access

Web- and app-based platform supplies customized process data to improve efficiency, reduce downtime and interface with data securely.

Photo Credit: Brown Machine Group

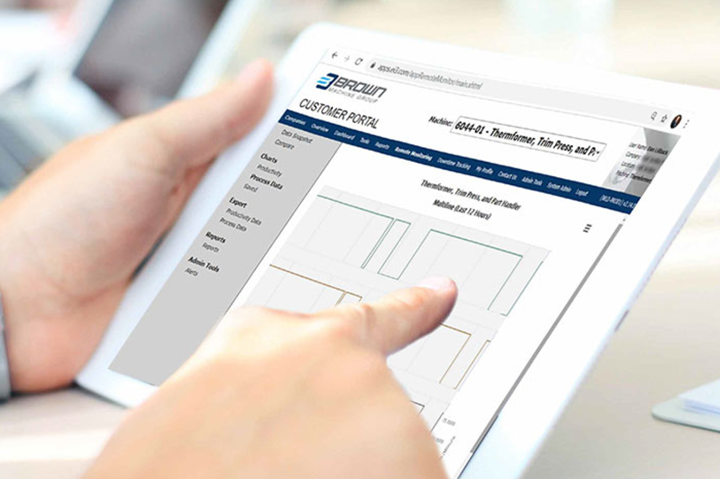

Brown Machine Group (BMG, Beaverton, Mich., U.S.) has launched the BMG Advanced Digital Readiness (BMG ADR) platform, a web- and app-based portal to access important process data in thermoforming and product handling applications. Available both with new installations and as a retrofit for most BMG machinery from the past several decades, ADR enables operators, maintenance personnel, operations teams and executive leadership to interface with equipment securely and in real-time.

According to Brown Machine Group, the BMG ADR platform is highly customizable to meet individual customer requirements, with unlimited custom alerts by text message or email, for a wide range of possible alarm conditions. Customization also enables users to review how critical assets are running, analyze unplanned downtime and improve operations through notifications when user-defined parameters are out of range.

The platform, available from anywhere via web browser or proprietary app, features enhanced security with automatic updates and allows customer-defined digital access to enable remote service sessions. Based on ei3’s Industrial Internet of Things (IIoT) approach, BMG says BMG ADR emphasizes the path toward smart equipment. Dedicated staff at Brown Machine Group are available to provide customers training and support.

Related Content

-

Plant tour: Sekisui Aerospace, Orange City, Iowa, Renton and Sumner, Wash., U.S.

Veteran composites sites use kaizen and innovation culture to expand thermoplastic serial production, 4.0 digitization and new technology for diversified new markets.

-

ST Engineering MRAS presents initiatives to drive autoclave efficiency, automation

During a JEC World 2024 panel discussion, the company revealed ways in which it is maximizing throughput and efficiency of its autoclaves and enhancing composites production processes.

-

SAM XL demonstrates closed-loop digital methodologies via full-size aerocomposite parts development

PeneloPe Project’s modular, zero-defect manufacturing deliverables are being highlighted in an upcoming video that demonstrates the resulting aerospace pilot line’s feasibility.