U.S. wind power added 9.1 GW in 2019

Total U.S. operating wind power capacity is now more than 105 GW, enough to power more than 32 million homes.

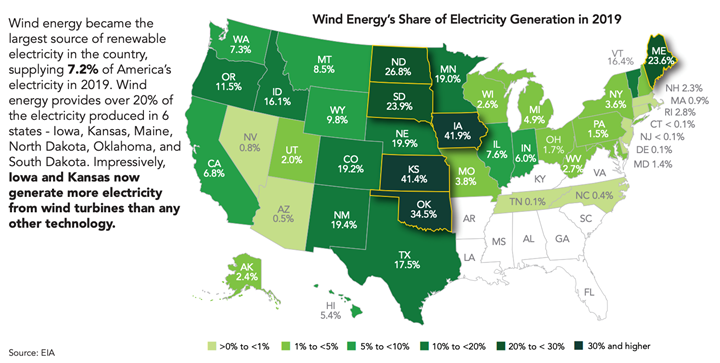

State-by-state percent of total energy generated provided by wind. Source | AWEA

The American Wind Energy Assn. (AWEA, Washington, D.C.) has issued its Wind Powers America Annual Report 2019, which shows that wind power emerged from 2019 as America’s top choice for new power after building 9.1 gigawatts (GW), representing 39% of new utility-scale power additions. With these additions, operating wind power capacity in the U.S. now stands at more than 105 GW, enough to power 32 million American homes. In addition, wind energy is now the largest provider of renewable energy in the country, supplying more than 7% of the nation’s electricity in 2019. The U.S. wind energy supports a record 120,000 American jobs, 530 domestic factories, and $1.6 billion a year in revenue for states and communities that host wind farms.

The U.S. wind industry experienced its third strongest year on record in 2019, as project developers invested nearly $14 billion in new wind projects totaling 9,137 MW. Total operating wind power capacity increased 9.6% to 105,591 MW, with nearly 60,000 wind turbines now operating across 41 states and two territories. This caps off a decade of growth that saw America more than triple its wind power capacity to become the largest renewable power resource on a capacity basis. Wind power represented 30% of utility-scale power plant installations over the past 10 years.

Texas and Iowa led the country in wind power additions, with both states installing individual record amounts of wind power for a single year. South Dakota had the largest percentage growth in 2019, increasing its installed wind capacity by more than 50% after installing 506 MW. In total, wind project developers delivered 55 projects in 19 states during 2019.

Wind energy also became the largest source of renewable electricity in the U.S. in 2019, generating more than 7% of the country’s electricity. To put into perspective, wind now generates enough electricity to meet the demands of California (the world’s fourth largest economy) and New Jersey combined. At the state level, wind provided more than 20% of the electricity generated in six states –Iowa, Kansas, Maine, North Dakota, Oklahoma, and South Dakota. In Iowa and Kansas, wind is now the single largest source of electricity generation. Both states generated more than 40% of their electricity from wind power last year.

Large-scale deployment of wind power has helped support grid reliability. Across the country, wind is key to keeping the lights on for American consumers and businesses. In the Southwest Power Pool, the grid across most of the Plains, wind met nearly 28% of total electricity demand in 2019 and at specific points in time represented nearly 70% of power generation. These types of records showcase the ability of grid operators to integrate very large amounts of wind power.

Another 44 GW of wind capacity is either under construction or in advanced stages of development. Those projects represent $62 billion in investment in the U.S. economy and enough additional power for 15 million American homes, once they’re built.

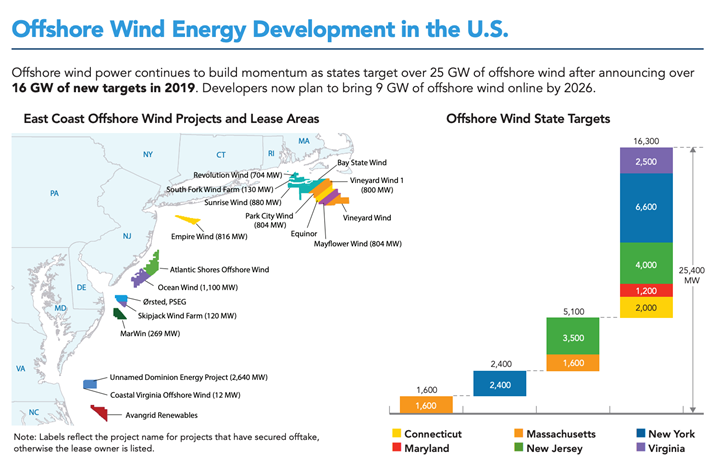

Offshore U.S. wind energy opportunities. Source | AWEA

Offshore, many states are looking to harness wind’s rapidly expanding opportunity. States up and down the East Coast are aiming to develop more than 25 GW of offshore capacity by 2035, with 16 GW of new targets announced in 2019 alone. To help meet these targets, states and utilities selected 4,404 MW of offshore wind capacity through state-issued solicitations in 2019.

“U.S. wind power has grown significantly over the past decade, as consumers across the country increasingly turn to wind to provide affordable, reliable, and clean electricity for their communities,” AWEA CEO Tom Kiernan says. “Years of hard work culminated with wind power becoming America’s largest renewable energy provider in 2019, with a 50-state footprint of job creation and economic development. Wind’s near-record project pipeline indicates this growth will continue for years to come. While we are now working to mitigate the significant disruptions from COVID-19, we know that we will meet these challenges with strong industry momentum.”

Related Content

Achieving composites innovation through collaboration

Stephen Heinz, vice president of R&I for Syensqo delivered an inspirational keynote at SAMPE 2024, highlighting the significant role of composite materials in emerging technologies and encouraging broader collaboration within the manufacturing community.

Read MoreComposites end markets: Batteries and fuel cells (2024)

As the number of battery and fuel cell electric vehicles (EVs) grows, so do the opportunities for composites in battery enclosures and components for fuel cells.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreComposites end markets: Energy (2024)

Composites are used widely in oil/gas, wind and other renewable energy applications. Despite market challenges, growth potential and innovation for composites continue.

Read MoreRead Next

Cutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreScaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read More