Three companies chosen to advance NASA deployable solar array

Astrobotic Technology, Lockheed Martin and Honeybee Robotics awarded $19.4 million to prototype build and test solar array systems to power moon exploration under Artemis. Current mast designs incorporate carbon fiber-based technologies.

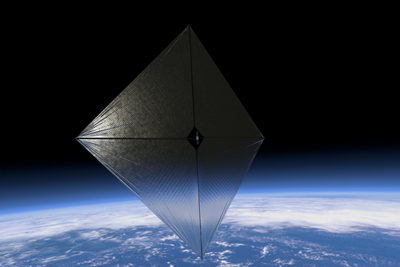

Vertical solar arrays, pictured in this illustration, will help power exploration of the moon under Artemis. Photo Credit: NASA

(Washington, D.C., U.S.) has selected three companies to further advance work on deployable solar array systems that will help power the agency’s human and robotic exploration of the moon under Artemis (updates on the Artemis I first uncrewed flight).

Through missions, NASA expects to return humans to the moon and establish a long-term presence near the lunar South Pole. A reliable, sustainable power source is required to support lunar habitats, rovers and even construction systems for future robotic and crewed missions. To help provide this power, NASA is supporting development of vertical solar arrays that can autonomously deploy up to 32 feet high and retract for relocation if necessary.

“These prototypes will provide promising solutions for reliable power sources on the moon, which are key to the success of almost anything we do on the surface,” Niki Werkheiser, director of technology maturation in NASA’s Space Technology Mission Directorate (STMD) at NASA headquarters in Washington, says. “This effort plays a critical role that will quite literally help power our Artemis exploration in the uniquely challenging environment of the moon’s South Pole.”

The agency has awarded a total of $19.4 million to three companies to build prototypes and perform environmental testing, with the goal of deploying one of the systems near the moon’s South Pole near the end of this decade. The designs must remain stable on sloped terrain and be resistant to abrasive lunar dust, all while minimizing both mass and stowed volume to aid in the system’s delivery to the lunar surface. The awards include:

- (Pittsburgh, Penn., U.S.): $6.2 million

- (Brooklyn, N.Y., U.S.): $7 million

- (Littleton, Colo., U.S.): $6.2 million

According to NASA, two out of three of these vendor designs (Astrobotic and Lockheed Martin) incorporate carbon fiber-based technologies for the masts.

Existing space-rated solar array structures are designed for use in microgravity or for horizontal surface deployment. The vertical orientation and height of these new designs will help prevent loss of power at the lunar poles where the sun does not rise very far above the horizon, according to NASA. When the sun is low on the horizon, the moon’s terrain can block some of its light, keeping it from reaching solar arrays that are low to the ground. By placing the solar arrays on tall masts, these designs enable uninterrupted light and therefore produce more power.

“We are excited to be able to select these three teams as they all bring very different technological solutions as well as unique visions for how commercial space can support a sustained presence on the moon,” says Chuck Taylor, Vertical Solar Array Technology (VSAT) project manager at NASA’s Langley Research Center (Hampton, Va., U.S.).

The contracts are part of the agency’s VSAT project, which aims to support NASA’s long-term lunar surface operations. In 2021, NASA to create initial designs for vertical solar array technologies. VSAT is led by STMD’s Game Changing Development program and Langley in collaboration with NASA’s Glenn Research Center in Cleveland.

Related Content

NASA launches composite solar sail into space

Sunlight-based propulsion system, supported by carbon fiber-reinforced booms, will undergo weeks-long testing to demonstrate and verify its capabilities.

Read MoreLow-cost, efficient CFRP anisogrid lattice structures

CIRA uses patented parallel winding, dry fiber, silicone tooling and resin infusion to cut labor for lightweight, heavily loaded space applications.

Read MoreCall for abstracts: CW Tech Days to explore high-temperature composite solutions

The fall 2025 installment of CW’s Tech Days online event series will cover high-temperature composite solutions for defense and space applications.

Read MoreExpanding high-temperature composites in India and the U.S.

Azista USA offers polymers and processes for carbon/carbon and other CMC, including novel hot-melt phenolic and phthalonitrile prepregs for faster cycle times, alternative solutions.

Read MoreRead Next

NASA develops advanced composite solar sail system

The ACS3 mission expects to demonstrate the successful deployment of the composite boom solar sail in low-Earth orbit to guide the design of future, larger-scale composite solar sail systems.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read More