Takeaways from International Conference on Sustainable Wind Turbine Blades 2022

Organizers and attendees lessons learned and outlook from November 2022 conference at DTU Risø in Denmark.

International Conference on Sustainable Wind Turbine Blades 2022. Photo Credit: ??

The was held Nov. 21-23, 2022 at DTU Risø (Roskilde, Denmark). Chaired by Dr. Leon Mishnaevsky, Jr. and Justine Beauson, the event hosted 120 participants including specialists from industry leaders Vestas, Siemens Gamesa, LM Wind Power, Arkema, Owens Corning, Aditya Birla Group and also from research centers such as DTU Wind and Energy Systems, National Renewable Energy Laboratory, Fraunhofer IFAM and ORE Catapult. These organizations shared their experience, results and goals for improving sustainability in wind turbine blades. Mishnaevsky is senior researcher at DTU Wind, and coordinator of projects “” and “.” Beauson is co-leading the international research network, the International Energy Agency (IEA) Wind Task 45 on the topic of wind turbine blade recycling.

In a , Mishnaevsky listed his first impressions:

- Recyclable wind turbine blades: There are several solutions for recyclable blade resins, including Recyclamine by Aditya Birla, Elium by Arkema, vitrimers by CIDETEC and others, bio-based versions of the materials. Some properties and technological aspects are still under validation, but the solutions are there.

- Recycling technologies: Again, the technologies are there. They require some modification, to ensure fibers retain their performance. Also, fiber sizing is the critical point, which will define the technology efficiency.

- Reuse: A relatively large amount of work deals with how and where to reuse the decommissioned blades or their parts. This looks like a working intermediate solution.

- Evaluation, feasibility, life cycle analysis (LCA): Here, a lot of work is underway. The analyses sometimes lead to surprising results (for instance, bio-based options are not always best for environment).

- Cost efficiency, supply chain, transportation, markets: These are the primary challenges. Blade recycling is expensive, and rules and policies vary in different countries and regions.

- Participation of policymakers and political advisors: It is not very common for policymakers and advisors to participate at technical conferences, however this wasn’t the case for this one. Apparently, policy and political decisions, not just technical developments, will shape the future of wind turbine sustainability.

According to Beauson, due to many ongoing research projects dedicated to the recycling of wind turbine blades, it is very important to ensure the information exchange between different project teams, in order not to repeat work already demonstrated elsewhere. Beauson observed that the strength of this conference was the representation of all main research projects occurring globally, as well as key stakeholders.

The conference included a number of presentation from participants involved in projects related to the end-of-life (EOL) of wind turbine blades, such as DecomBlades, SusWind, Rekovind, Zebra, Cetec, Ecoxy, Blades2Build, ReWind and EcoBulk. The participation of industries, universities and public authorities was also key to fruitful discussions, where all opinions were represented. Another important aspect of this conference, Beauson notes, was the multidisciplinary approach — the conference hosted presentations on recycling technologies with technical discussions, but also addressed the value chain perspective, the economic dimension of blade recycling, as well as the social and environmental impacts.

Attendee Nina Vielen-Kallio also gave . Vielen-Kallio is a project manager at ECHT (Utrecht, Netherlands), an agency aimed at accelerating the energy transition, and the startup accelerator VentureLab North (Groningen, Netherlands), as well as the founder of the digital platform eWEning star, also seeking to accelerate the energy transition by increasing the efficiency of information discovery in the renewable energy sector.

“The conference was mind blowing,” Vielen-Kallio says, “featuring 43 presentations about sustainability, circularity of wind turbine blades in 2.5 days!” Her high-level takeaways included:

- Lack of data is a massive challenge and hinders objective research. Incomplete data leads to wrong conclusions.

- “Rediscovering data adds costs” by Paul Leahy. Their group was able to cut costs by almost 50% when implementing lessons learned from a first application (bridge from wind turbine blades) to a second application.

- A massive amount of research has been performed regarding circularity for wind turbine blades: Expected volumes, technologies, material properties after processing, etc.

- Some research papers are actually literature reviews (approximately half when it comes to decommissioning processes according to Kristine Wilhelm Lund), meaning new papers don’t necessarily mean new information.

- DTU – Technical University of Denmark organized a great conference with a very interesting slate of speakers and topics.

Learn more about the conference .

Related Content

Airbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

Read MoreJEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreWatch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

Read MoreRead Next

DNV, Reodor Studios create digital service for sustainable wind farm decommissioning

New ReWind service will enable recyclability assessment and sustainable end-of-life planning for wind turbines.

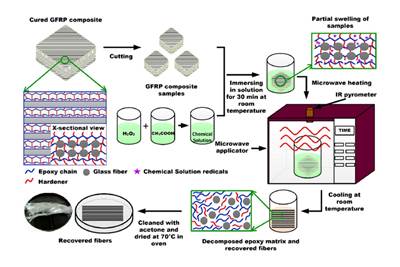

Read MoreIIT Mandi researchers use microwaves, eco-friendly chemicals to recover glass fibers

Development of a rapid, sustainable microwave-assisted chemical recycling process targets decommissioned wind turbine blades, promotes decreased landfill disposal.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More