Suprem SA begins new pultrusion line production

Highly automated manufacturing line processes continuous fibers with high-performance thermoplastics for tapes, profiles and rods.

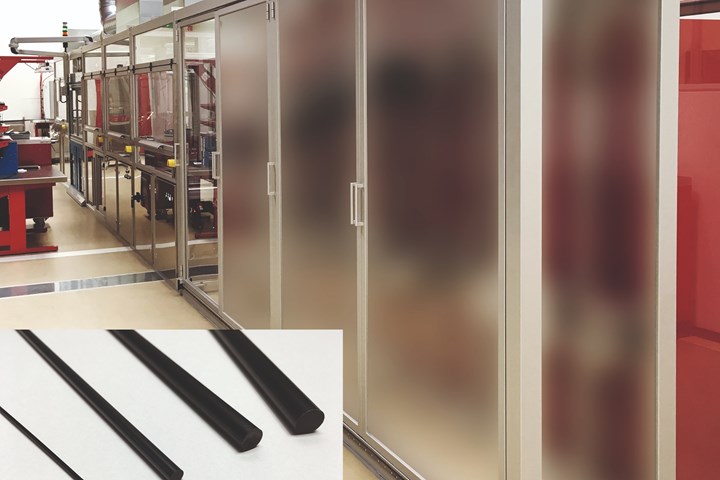

Photo Credit: Suprem SA

Suprem SA (Yverdon-les-Bain, Switzerland) reported on Jan. 25 that it is leveraging its decades of thermoplastic composite materials into a new pultrusion line.

The company says the advanced machinery enables the combining of continuous fibers (carbon, glass and aramid fibers) with high-performance thermoplastics (PA to PAEKs) into rods and profiles.

The pultrusion line and its dedicated production hall are said to fulfill stringent requirements in terms of cleanliness, manufacturing process validation and quality control. Both assets are qualified for medical applications and can be used for other demanding markets, Suprem SA says.

Together, with current production equipment, innovative and customized products such as tape, profiles and rods can also be offered for automated additive manufacturing processes.

“After several years of development, I am proud of the team, which has mastered a technological breakthrough with a highly automated manufacturing line,” says Dr. Anatole Guilliot, CEO, Suprem SA. “It is an important milestone and a commitment to our customers to maintain the quality benchmark on thermoplastic composite material market. We are looking forward to further supporting our customer’s projects with high quality and reliable products for automated processing.”

Related Content

-

Composite wrap system combats corrosion in industrial tank repair

A fiberglass and carbon fiber composite wrap system enabled an Australian nickel mine to quickly repair a stainless steel ammonium sulphate feed tank and protect against future corrosion.

-

Polaris Spaceplanes receives MIRA II, MIRA III fiberglass airframes

German aerospace startup prepares next demonstrators toward reusable space launch and hypersonic transport toward routine, low-cost and safe access to space.

-

ORNL demonstrates lightning strike protection tech for composites

Researchers, led by Vipin Kumar, developed a low-cost, recyclable carbon fiber wind turbine blade tip that showed resilience to high-voltage lightning strikes, with more innovations in store.