Smart, self-powering composite from DITF uses a "textile power plant" concept

Multilayer fabric-based piezoelectric elements and pyroelectric energy harvesters reinforce the FRP structure, generating electrical energy using vibration, oscillation and temperature fluctuation.

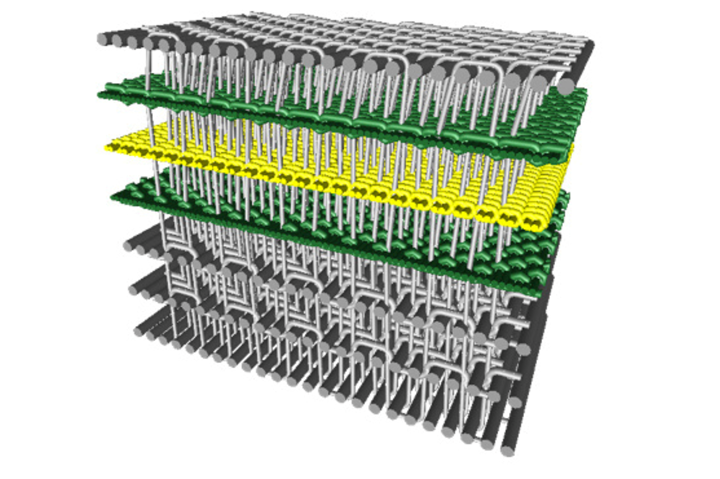

Schematic representation of the multilayer woven textile structure of the textile power plant. Photo Credit: DITF

According to the German Institutes of Textile and Fiber Research (DITF, Denkendorf), which offers expertise in fiber optic and piezoelectric sensors (see “DITF develops textile sensors for composites”), smart fiber-reinforced plastics (FRP) have much to offer. Alongside this opportunity, DITF says there is also a need to consider how integrated arrays of sensors and actuators can actually be powered. With this in mind, DITF has developed a multilayer textile, an in-built “textile power plant” that can generate electrical energy using vibration, oscillation and temperature fluctuation. This would reportedly allow the smart composite used in an electric vehicle (EV), for instance, to harness power from its own motion. In general, the significance of the research project will add further capability to the composite, making it lightweight and smart, in addition to acting as its own power plant.

According to , an industry consultant, visiting professor at the Royal College of Art (RCA, London, U.K.) and author of several books on advanced and smart textiles, piezoelectric and pyroelectric principles are employed. The textile reinforcement structure for the FRP provides for the generation of electrical energy using the piezoelectric effect to harness vibration, while the pyroelectric effect generates electrical energy from waste heat. Since polyvinylidene fluoride (PVDF) has both piezoelectric and pyroelectric properties and is available as a yarn, it is possible to create “textile generators” based on multilayer fabrics to be developed for both principles.

The functional principle is demonstrated in this project with a smart, self-powering composite. Vibration occurs through moving parts and friction, while waste heat is generated in EVs, for example, at the battery — or, in the case of vehicles with conventional combustion engines, through the combustion of the fuel. The technology is expected to be used both in conventional cars with combustion engines, as well as EVs, O’Mahony mentions.

There are two specific areas of development in the project. The first is a piezoelectric energy harvesting system based on a multilayer fabric structure designed to harness vibration as an energy source. The second is a woven pyroelectric generator for the use of waste heat as an energy source.

First, multilayer fabric-based piezoelectric elements were developed and characterized as a reinforcement structure for FRP. This structure is intended to be used in high-vibration areas of the vehicle to generate electrical energy. The tests carried out at the DITF show that even the slightest vibrations can lead to a significant charge displacement in the material and thus generate electrical energy.

Based on this technology, pyroelectric energy harvesters have been developed. These are analogous to the pyroelectric energy harvesters and have been constructed from the multilayer fabric structures and characterized in terms of their recuperation properties. Because the vehicle is equipped with large-surface components that are exposed to vibrations, deformations and temperature fluctuations, through these smart composite materials, previously unused waste energy can be made usable.

Related Content

Mold 3D printing helps automate composite bathtub, shower production

As part of its efforts to automate as much of its production process as it can, Lyons Industries acquired a Massivit 10000 additive manufacturing system to quickly produce high-performance molds and support fixtures.

Read MoreLaser cleaning in composites manufacturing

Laser cleaning technologies for cleaning production molds for composites offer alternatives to harsher, less-friendly methods with features like automation and higher power cleaning.

Read MoreTAVieDA project team cuts aircraft door production time using thermoplastic composites, welding

Fraunhofer groups, Trelleborg and Airbus develop modular, fully automated assembly system concept to replace metals and time-consuming assembly that shows potential for scalability.

Read MoreFlyber launches U.K. composites manufacturing site for advanced mobility applications

The startup’s design automation and composite material layup and curing technologies target lightweighting for aerospace, UAVs, eVTOL and high-performance mobility platforms.

Read MoreRead Next

Scaling up, optimizing the flax fiber composite camper

Greenlander’s Sherpa RV cab, which is largely constructed from flax fiber/bio-epoxy sandwich panels, nears commercial production readiness and next-generation scale-up.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More