SGL Carbon, Koller Kunststofftechnik manufacture composite windshield

Injection molded carbon fiber profiles for future BMW Group models cut 40% of weight compared to conventional steel construction and offer potential use in other automotive projects.

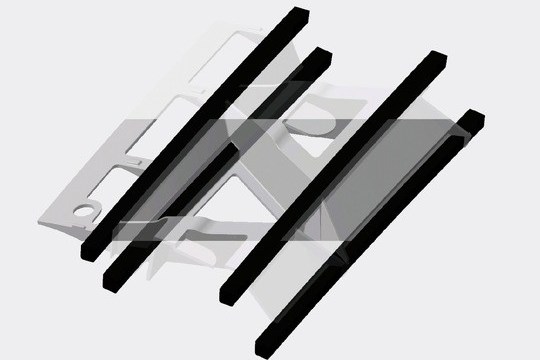

Skeletal windshield design. Photo Credit: SGL Carbon

In August 2020, SGL Carbon (Wiesbaden, Germany) received a multi-year order from (Lupburg, Germany) for the production of novel carbon fiber profiles for serial use in windshields, which will be applied in a high-volume model of BMW Group (Munich, Germany) within the next few years.

According to SGL Carbon, the profiles are composed from flexible fiber tows, pre-impregnated with thermoplastic resin in various dimensions. They will be compiled by SGL Carbon on the basis of its own 50K carbon fiber at its site in Innkreis, Austria, and subsequently processed by the injection molding experts at Koller to form a skeletal plastic component (More on this design with “Skeleton design enables more competitive composite autostructures” and “More details on MAI Skelett design process”). The composite component will reportedly replace the previous steel-based windshield. Production of the carbon fiber profiles will start in the remainder of 2020 and will then be ramped up gradually over the next few years for the BMW Group model launch.

As a vehicle’s windshield typically has an important stabilizing function, says SGL Carbon, the carbon fiber profiles add the required stiffness and crash safety to the component. At the same time, they are said to significantly reduce the weight of the roof and also support the driving dynamics. The injection molding process also enables particularly complex and material-efficient structures. In the BMW Group model, this innovative component concept will cut weight by 40% compared to conventional steel designs of the component, while creating important space for cable ducts and sensors.

SGL Carbon adds that the production of the carbon fiber profiles themselves is also particularly geared to material and process efficiency in large-scale production. The profiles consist of several smaller fiber strands — called “rods” — and are manufactured using the modern continuous pultrusion process. During product and process development it was one key objective to ensure that material loss during production was almost completely avoided.

"At SGL Carbon, we have been working on the development of thermoplastic carbon fiber profiles for use in injection molding for some time already. This developmental work is now beginning to pay off. Due to the many advantages and competitive costs, we see a great potential for the technology to be used in other automotive projects too," explains Sebastian Grasser, head of the Automotive Segment in the Business Unit Composites – Fibers and Materials at SGL Carbon.

"Innovative lightweight construction with hybrid designs has developed into a strategically conclusive concept for Koller Group's OEM customers," confirms Max Koller, CEO of Koller Group. "SGL Carbon's high level of material expertise, combined with the process know-how of Koller Kunststofftechnik and Koller Formenbau, create the basis for a promising future in innovative lightweight construction technologies. With this order, the BMW Group has confirmed its confidence in the successful cooperation between SGL and Koller; we are particularly pleased about this,” he adds.

The Koller Group is a globally operating technology company with plants in Europe and China, as well as NAFTA. The Koller Group develops and manufactures lightweight construction, tools and serial components, primarily for the automotive industry.

Related Content

Reinforce 3D receives €1.2 million investment to support 2025 growth plans

Production, R&D team and strategic market expansion will scale up the company’s continuous carbon fiber injection technology, composite capabilities.

Read MoreFraunhofer IGCV develops helicopter door shell using SMV composite

SMC-replacement material subjected to vario-thermal pressing cycle achieved a 1.2-millimeter-thick, complex-shaped door shell, demonstrating feasibility for future aerospace components.

Read MoreReinforce 3D forms alliance with 3D printing company Spring Srl

Integration of CFIP technology with additive manufacturing will facilitate optimized composites manufacturing and build up CFIP’s scale.

Read MoreNIAR innovates overmolded TPC production process for eVTOLs

Fully automated hybrid thermoforming and injection overmolding process was executed to produce complex thermoplastic composite rib structure in 2 minutes versus 100-hour metal counterpart.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read MoreNext-gen fan blades: Hybrid twin RTM, printed sensors, laser shock disassembly

MORPHO project demonstrates blade with 20% faster RTM cure cycle, uses AI-based monitoring for improved maintenance/life cycle management and proves laser shock disassembly for recycling.

Read More