Safran Nacelles Morocco installs large autoclave, doubles cleanroom per development plan to increase production rates

Extension of 6,000 square meters dedicated to Gulfstream G700/G800 production, groundwork laid to digitalize processes and reduce environmental footprint.

Located in Nouasseur, near Casablanca Airport, the Safran Nacelles plant in Morocco specializes in the production of composite parts and the assembly of thrust reversers/nacelles and sub-assemblies. Photo Credit: and

Safran Nacelles Morocco (Spain) inaugurates the extension of its aircraft nacelles production site. The extension of nearly 6,000 square meters is dedicated to the production of the Gulfstream G700/G800 business aircraft nacelles. The site will become even more efficient through an industrial development plan which will enable increased nacelle production rates for customers.

Photo Credit:

Safran Nacelles Morocco, established in March 2005, is reported to be the largest aerospace production site in Morocco. It specializes in the manufacture of composite materials and the assembly of nacelles — air inlet, engine cowls and thrust reversers — and their sub-assemblies. Through its presence in the territory, the company has developed a local logistics chain with the support of the Group of Moroccan Aeronautics and Space Industries (GIMAS).

Photo Credit:

Safran has invested €11 million in the site, which reportedly integrates the highest standards in the aviation industry. It thus becomes Safran’s reference site in Morocco, supporting a strong ambition to digitalize its production processes and reduce its environmental footprint.

Photo Credit:

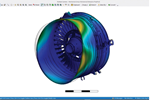

Safran Nacelles Morocco enters the “Manufacturing 4.0” era by incorporating state-of-the-art equipment such as a large autoclave, ergonomic workstations, machining equipment and the latest generation of robots and cobots. The site has also doubled its cleanroom surface dedicated to the manufacture of composites, from 1,800 to 3,600 square meters.

To support its development, Safran Nacelles Morocco is training its 850 qualified nacelle manufacturing, composites and assembly personnel, so that they can develop new skills, particularly in engineering. One hundred new employees will be joining the company to strengthen its workforce over the course of this year.

“Safran provided its support for the development of skills and maturity in this industry, and the interest the group is taking in the Moroccan aerospace platform and its human capital contributes to the strengthening of the sector's competitiveness and the integration of higher value-added activities,” Ryad Mezzour, Morocco’s minister of industry and trade, says. “Morocco is now entering a new aerospace industry era that will make our country a center of technology and excellence and will enable it to gain a position as a major player on a global scale.”

In order to help reduce Safran’s CO2 emissions by 30% from 2025, the site is now equipped with a power plant supplied by 3,000 photovoltaic panels installed on the new extension and on the site’s car parking carport. It will produce 20% of the site’s electricity and, once it is operational in August 2022, will save 2,000 tons of CO2 each year.

Related Content

-

Busch expands autoclave solutions

Busch announces its ability to address all autoclave, oven and associated composites manufacturing requirements following the acquisition of Vacuum Furnace Engineering.

-

Industrial curing autoclaves with advanced control systems

CAMX 2025: Turnkey Akarmak autoclaves support various composite curing needs with enhanced process control, international specification compliance and optimal heat distribution.

-

Industrial composite autoclaves feature advanced control, turnkey options

CAMX 2024: Designed and built with safety and durability in mind, Akarmark delivers complete curing autoclave systems for a variety of applications.