Researchers use graphene-based TENGs to provide energy sources for future smart devices

A new study proves that using an advanced type of 3D graphene foam as an active layer in triboelectric nanogenerators (TENGs) can work as a reliable and cost-effective energy harvesting power source for autonomous sensors and electronics.

UWS self-powered pressure mat via Gii-TENG. Photo Credit: Integrated Graphene

Researchers from the (ITFSI) from the University of the West of Scotland (UWS, Paisley), have explored the use of the 3D graphene foam material Gii by (Stirling, U.K.) as an active layer in an energy generator known as a triboelectric nanogenerator (TENG). The investigation aimed to transform mechanical energy wasted in nature into electrical energy that could be used to power small electronic devices and sensors in the booming global market for Internet of Things (IoT) technologies.

The research, published in , shows that the force of a human footprint on a pressure-sensitive mat, equipped with Gii-TENG sensors, can produce enough energy to anonymously identify people entering or leaving a room. As well as providing a low-cost and energy-efficient solution to monitoring building occupancy, the mats could also help to optimize energy resources by, for example, controlling room temperature upon entrance or exit.

The findings of this study will be of particular interest to schools and universities who could employ the technology to link the measurement of room occupancy to a ventilating system and a CO2 monitor, reducing the volume of CO2 which has been shown to reduce the ability to focus.

Mechanical energy is one of the most abundant and versatile energy sources available in nature. For around 20 years, TENGs have been investigated as a technique for converting mechanical energy from our daily actions into usable electrical energy which can power both small IoT electronic devices and sensors but also more power-hungry items such as electric cars and drones.

However, efforts to develop a commercially viable TENG have, to date, been hampered by issues relating to low durability, limited energy output and inefficiency. The addition of Gii to TENG has reportedly opened up a new world of possibilities due to its properties including high surface area, porosity, light weight and improved electrical properties. According to researchers, the energy autonomous, pressure-sensing nature of Gii-TENG has the potential to transform various aspects of our lifestyles, society and economy including, for example:

- Harvesting energy from sports such as golf, running and tennis to power smart devices which generate performance data.

- Self-powered wearable biosensors for early diagnosis of health conditions including cardiovascular disease, gout and diabetes.

- Harvesting energy from cars on roads and people walking in the creation of smart cities.

- A smart energy solution for Industry 4.0.

- Extending the hovering time of drones, enabling transportation of parcels — and even people in the future — for longer distances and longer times.

“With the number of IoT devices interlinked worldwide forecast to reach 100 billion by 2030, there is a clear need for new sustainable energy sources and technologies which can meet the power demand from our reliance on technology for work, life and play,” Marco Caffio, CSO, Integrated Graphene, says. “Our Gii-TENG platform could potentially prevent the constant replacement of batteries in trillions of devices, and reduce the use of wires, making the IoT technology of the near future to be wireless and energy autonomous.”

Related Content

On the radar: Innovations in composite battery enclosures

A look at recently reported design, material and process innovations for composites-intensive battery enclosures, developed to support the ramp-up of EV and AAM vehicles.

Read MoreHydroGraph ramps up efforts to scale pristine graphene offerings

Purchase orders for autocomposite improvement program, patent application filings and additional certifications push the graphene producer on its path forward to commercialization for composites, coatings and lubricants, to name a few.

Read MoreKCARBON and KIST develop lyocell/PLA/wood biocomposites

Initial demonstration in furniture shows properties two to nine times higher than plywood, OOA molding for uniquely shaped components.

Read MoreMito to introduce graphene to EV energy storage innovations

Project initiatives for a multifunctional adhesive and addressing EV battery challenges are expected to change the dynamics of energy storage adoption.

Read MoreRead Next

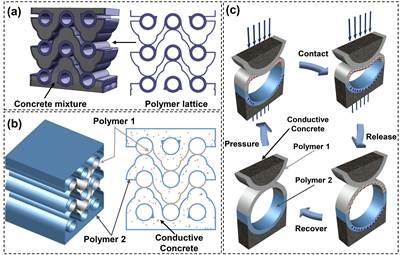

21st century concrete: composite metamaterial with super compressability, energy harvesting

Material comprising 3D-printed, auxetic, reinforced polymer lattices in conductive cement matrix can compress up to 15% and generate electricity for lightweight, mechanically tunable structures with energy harvesting and sensing.

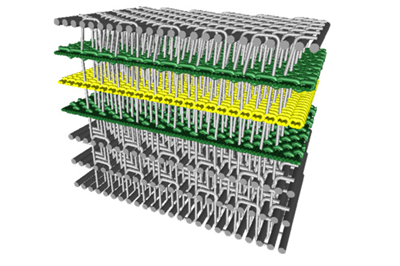

Read MoreSmart, self-powering composite from DITF uses a "textile power plant" concept

Multilayer fabric-based piezoelectric elements and pyroelectric energy harvesters reinforce the FRP structure, generating electrical energy using vibration, oscillation and temperature fluctuation.

Read MoreCeramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read More