Researchers develop liquid crystal polymer spin-printing process for recyclable composites

ETH Zürich, TU Delft and EMPA simultaneously 3D prints parts with spun fiber reinforcement for stronger, more sustainable, fully recyclable components.

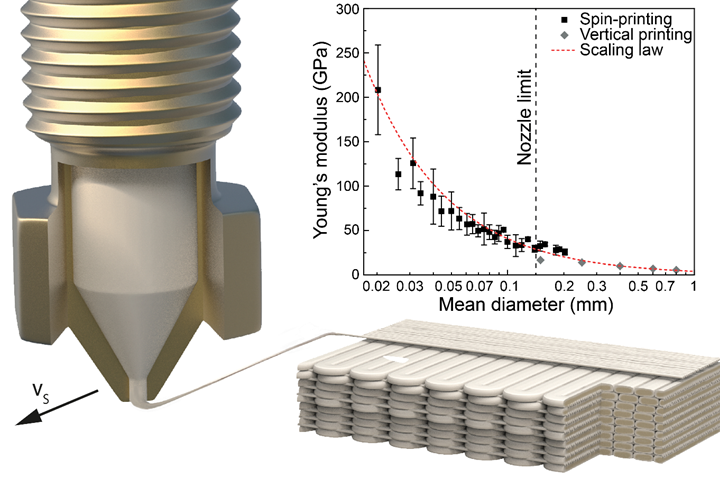

Thinner diameters obtained by fiber spinning lead to extremely high Young’s modulus. Photo Credit: Chiara Mascolo

Researchers from ETH Zürich’s (Switzerland) , Delft University of Technology’s (TU Delft, Netherlands) and (Switzerland) have developed a new process to 3D print liquid crystal polymers. This process enables an object to be printed, while simultaneously spinning reinforcing fibers into it, in the same way a spider spins its web.

According to Associate Professor Kunal Masania, reinforcing parts with fibers according to the part’s load case enables a more efficient use of materials, as well as reduced weight and enhanced mechanical properties. However, the composites industry still faces two primary challenges: More often than not, composites are not able to be fully recycled (and when they are, their afterlife consists in much less demanding applications), and the manufacturing processes involves several tedious steps that are cost, labor and energy intensive.

Therefore, Masania says, through this project, researchers sought to create a process that develops fully recyclable parts that are as strong as carbon fiber-reinforced polymers (CFRPs) while also being much more sustainable. “We show that with one single polymer, you can print strong reinforcements to a part on-the-fly to match the mechanical loading condition of its future application. The fact that only one single polymer is used greatly facilitates recyclability,” Masania says.

“The main challenge was to be able to print fibers as thin as possible with a uniform diameter throughout its length,” he continues. “Thanks to the models we derived, we are able to reach consistent diameters down to 20 microns, less than a 1/5 of a human hair. This enables us to harness the natural tendency that LCP molecular chains have to self-orient.” The resulting spun fibers were able to reach tensile modulus and strength of 208 GPa and 2.6 GPa respectively. “This can be seen as quite a feat, for two reasons,” Masania adds. “The tensile modulus is in the range of that of carbon fibers, yet those fibers are created from a simple desktop 3D printer with low processing energy.”

Compression tests of bamboo-inspired reinforced cylinders. Photo Credit: Chiara Mascolo

Next steps will be to integrate this concept into more complex architectures and more create functional objects with some important applications such as space components, passive damping elements and pressure vessels.

Project researchers include Silvan Gantenbein, Chiara Mascolo, Caroline Houriet, Robert Zboray, Antonia Neels, Kunal Masania and André R. Studart, some of who have also founded the startup to commercialize the novel material and printing process.

More on this project can be found , or contact authors Andre Studart (andre.studart@mat.ethz.ch) and Kunal Masania (K.Masania@tudelft.nl).

Related Content

-

Damage tolerance testing of sandwich composites: The sandwich CAI test

A new ASTM-standardized test method established in 2022 assesses the compression-loaded damage tolerance of sandwich composites.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.

-

Corebon induction heating

This sidebar to CW’s August 2024 feature article reviews this technology for more efficient composites manufacturing and why it aligns with Koridion active core molding.