Permali develops fire-resistant systems for naval vessels

Permali has developed Permaglass XGR2/4, a new specialist fire-resistant composite material grade that passes strict Ministry of Defence regulations.

(Gloucester, U.K.) designs and manufactures high-strength, glass fiber-reinforced (GRP) composite stanchions, guardrails, deck safety net frames and ladder systems for naval warships and support vessels.

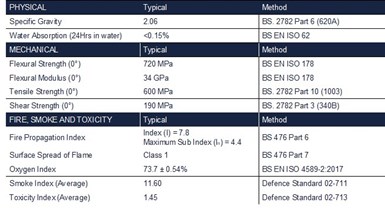

To meet the latest U.K. Ministry of Defence (MoD) regulations, Permali’s R&D team has developed Permaglass XGR2/4, a new specialist fire-resistant (FR) composite material grade. Defence Standard 07-247 is the latest, more stringent MoD fire, smoke and toxicity (FST) performance standard for naval vessels. Permaglass XGR2/4 achieved the highest overall Category A1 rating possible for this enhanced FST Def standard; critical XGR2/4 fire test coupons achieved Class 1 for surface spread of flames (to BS 467 Part 6) and a fire propagation index (I) of 7.8 (to BS 467 Part 7).

Permali’s new Permaglass XGR2/4 resin grade and laminate system achieves this higher FST rating while still meeting the demanding mechanical performance requirements of the MoD standard. Permali has been able to do this by combining its proprietary high-performance, low volatile organic compound (VOC) thermoset FR resin formulation with woven glass reinforcements. Typical mechanical properties include a flexural strength of 720 MPa (to BS EN ISO178) and a tensile strength of 600 MPa (to BS 2782 Part 10:Method 1003).

Current naval vessels in service fitted with Permali supplied deck safety systems include: Visby class corvettes; RN Type 45 destroyers and Type 23 frigates; RFA Bay class support ships; and the Queen Elizabeth-class aircraft carriers, said to be the biggest, most advanced warships built for the Royal Navy. In addition to naval ships, the specialist polar exploration vessel, the RRS Sir David Attenborough, is also fitted with Permali deck safety systems to protect personnel while on the flight deck.

The use of a GRP composite material for stanchions, guardrails and net frames reportedly provides key in-service benefits over metallic alternatives, says Permali, including being lightweight, vibration free, corrosion resistant, low maintenance and non-conductive. For warships, Permali’s composite stanchions produce a significantly reduced radar detection signature.

According to the company, Permali offers a complete range of durable deck or hull mounted modular GRP composite stanchion designs to provide rigid guardrails, Parafil synthetic rope guardrails and safety nets or removable chains. Four standard stanchion styles are manufactured to accommodate the different types of vessels and deck area safety requirements:

- Type A stanchions (for fixed position guardrails)

- Type B stanchions (can fold fore and aft of the deck)

- Type D stanchions (fold onto the deck)

- Quick Release/Removable stanchions (for access areas)

RRS Sir David Attenborough, fitted with Permali deck safety systems. Photo Credit: Permali

Stanchion systems are supplied by Permali complete with all the stainless steel deck base fixings, positive lock fittings and lug bolts specified for guardrail and net system designs. All fabricated composite stanchions, rigid guardrails, “quick release” lift off gates and deck safety net frames are finished in-house with a two-part paint system. Lift off gates are installed to provide easy access to specific deck areas for “over the side” replenishment at sea (RAS) and to enable unobstructed helicopter maintenance.

Related Content

FibreCoat develops radar-absorbing fiber-reinforced composite

Broadband, flexible material offers protection against radiation, heat and electromagnetic interference, and maintains performance across curved surfaces and slanted angles, outperforming existing materials by up to 100 times.

Read MoreTenCate Advanced Armour renamed to Integris Composites

With its rebranding, Integris maintains the ability to develop, test and manufacture ballistic armor and survivability solutions while expanding into new markets where composite solutions can be advantageous.

Read MoreIndustrializing additive manufacturing in the defense/aerospace sector

GA-ASI demonstrates a path forward for the use of additive technologies for composite tooling, flight-qualified parts.

Read MoreFrom the CW Archives: Airbus A400M cargo door

The inaugural CW From the Archives revisits Sara Black’s 2007 story on out-of-autoclave infusion used to fabricate the massive composite upper cargo door for the Airbus A400M military airlifter.

Read MoreRead Next

All-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read MoreAssembling the Multifunctional Fuselage Demonstrator: The final welds

Building the all-thermoplastic composite fuselage demonstrator comes to an end with continuous ultrasonic welding of the RH longitudinal fuselage joint and resistance welding for coupling of the fuselage frames across the upper and lower halves.

Read More