Nordic Bioproducts successfully spins novel plant-based textile fiber

The Finnish startup begins an intensive product development period to scale up its Norratex fiber, which is manufactured without toxic chemicals or expensive solvents.

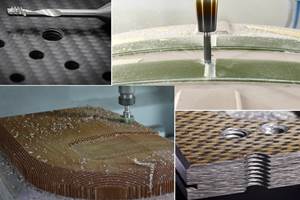

Norratex wet spinning process. Photo Credit, all images: Photino Science, Pentti Pällijeff

(NBG, Espoo, Finland) reports that it has successfully spun a new plant-based textile fiber, Norratex, which is manufactured without any toxic chemicals or expensive solvents. At a recent press conference, the company also revealed its collaboration with CMPC Ventures (Santiago, Chile), the Corporate Venture arm of CMPC S.A, one of the largest producers of pulp in the world.

The Finnish startup company is a spin-off from Aalto University that develops and commercializes smart biotechnologies to redesign cellulose into high-value bioproducts; it is the proprietor of the patented AaltoCell which has opened new markets for microcrystalline cellulose.

According to NBG, new and sustainable alternatives from wood- and plant-based feedstock are required to address the sustainability challenges of the textile industry. The market for sustainable, man-made cellulosic fibers is also expected to grow above 10% within the next decade. The company lists several Finnish innovations in this field that are ramping up textile fibers, from Spinnova Oy (Jyväskylä), Metsä Spring Oy (Espoo), Kuura (Espoo) and Infinited Fibre Co. (Espoo), to Aalto University’s Ioncell fiber.

To produce Norratex, the cellulose is first hydrolyzed in an environmentally friendly, cost-effective manner. The fiber is then processed further into a viscose-like textile fiber. The inventor of the AaltoCell method, Professor Olli Dahl at Aalto University, was convinced from early on that the method, developed by NBG, could be applied in the production of plant-based textile fibers, as the Norratex method can use a wide variety of raw material sources, such as forest industry byproducts, textile waste and ordinary paper pulp; this is said to be a significant advantage over traditional viscose, which is made from dissolving pulp and can have a cost 30% higher than paper pulp.

“It’s great to see when your own ideas lead to new products by the skillful team of engineers in a young company. We are embarking on a new era in developing novel bio-based products,” Dahl says.

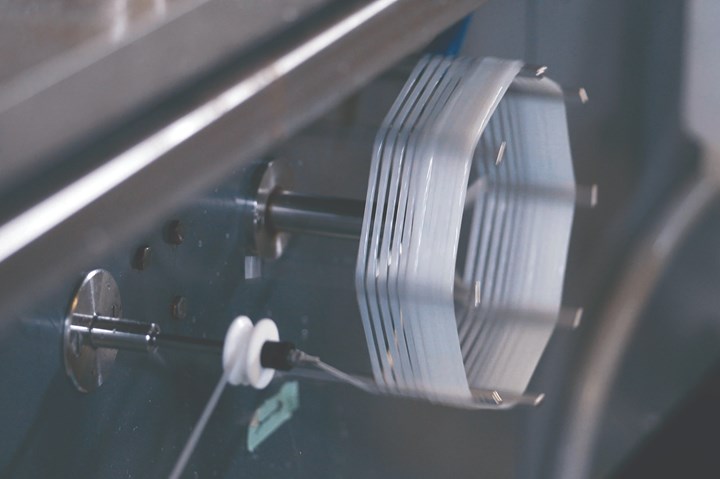

Norratex fiber (above) and sample (below).

In 2020, NBG began to develop a cost-effective and scalable textile fiber manufacturing process in collaboration with the University of Tampere (Finland), based on Dahl’s idea. NBG’s team of chemical and fiber processing engineers were able to find just the right parameters for the dissolution that enables wet spinning of the cellulose dope.

The first wet spinning experiments with NBG’s cellulose dissolution method were performed in June 2021. Six months later, in November 2021, yarn was successfully produced via the Norratex textile fiber at the University of Tampere. Several samples of the yarn were knitted at the Department of Design at Aalto University.

Maija Järventausta, a researcher who carried out wet spinning and yarn production in Tampere, describes the success. “The seventh spinning experiment really surprised me. The dope was excellent and it did not clog the spinneret during wet spinning. At that moment, I suggested that we should try making yarn for the first time. In the next step, the carding was successful, the fiber withstood opening, curled beautifully and no pilling was formed. Fiber-to-fiber friction was optimal. I would never have believed that in such a short period of product development, one could succeed in a functional end product. It was great to see that the yarn was strong enough not to break in the knitting process. The yarn also has a beautiful, subtle gloss, a feature that lasted from wet spinning to the dry yarn.”

Several partners are now involved in the development and commercialization of the new fiber, the most important of which is CMPC Ventures. “Collaboration patterns are central to the success of the project,” says Olli Kähkönen, co-founder and innovation director at Nordic Bioproducts, emphasizing the scale of the project. “We are partnering with CMPC to begin an intensive product development period of approximately one year. After that, if everything goes as planned, we will start producing Norratex textile fiber on a pilot scale.”

Related Content

Biomaterials make strides toward composites sustainability

A compilation of trends in development or application of natural fibers, bio-based resins and more showcases industry players, educational institutes and global projects.

Read MoreOptimizing machining for composites: Tool designs, processes and Industry 4.0 systems

Hufschmied moves beyond optimized milling and drilling tools to develop SonicShark inline quality control system and Cutting Edge World cloud platform for optimized tool use and processes.

Read MoreJEC World 2024 highlights: Glass fiber recycling, biocomposites and more

CW technical editor Hannah Mason discusses trends seen at this year’s JEC World trade show, including sustainability-focused technologies and commitments, the Paris Olympics amongst other topics.

Read MoreNotox surfboards harness flax fiber for wave surfing competition

Libeco flax, Airbus rCF fabrics, Sicomin GreenPoxy bioresins and an agave core form a heavy, robust surfboard custom-designed for Clément Roseyro in this year’s Nazaré Big Waves Surf event.

Read MoreRead Next

Composites end markets: New space (2025)

Composite materials — with their unmatched strength-to-weight ratio, durability in extreme environments and design versatility — are at the heart of innovations in satellites, propulsion systems and lunar exploration vehicles, propelling the space economy toward a $1.8 trillion future.

Read MoreAll-recycled, needle-punched nonwoven CFRP slashes carbon footprint of Formula 2 seat

Dallara and Tenowo collaborate to produce a race-ready Formula 2 seat using recycled carbon fiber, reducing CO2 emissions by 97.5% compared to virgin materials.

Read MoreVIDEO: High-volume processing for fiberglass components

Cannon Ergos, a company specializing in high-ton presses and equipment for composites fabrication and plastics processing, displayed automotive and industrial components at CAMX 2024.

Read More