NCAMP qualifies Teijin carbon fiber-reinforced thermoplastics

This represents the first qualification of a carbon fiber fabric-reinforced thermoplastic composite material by the National Center for Advanced Materials Performance (NCAMP).

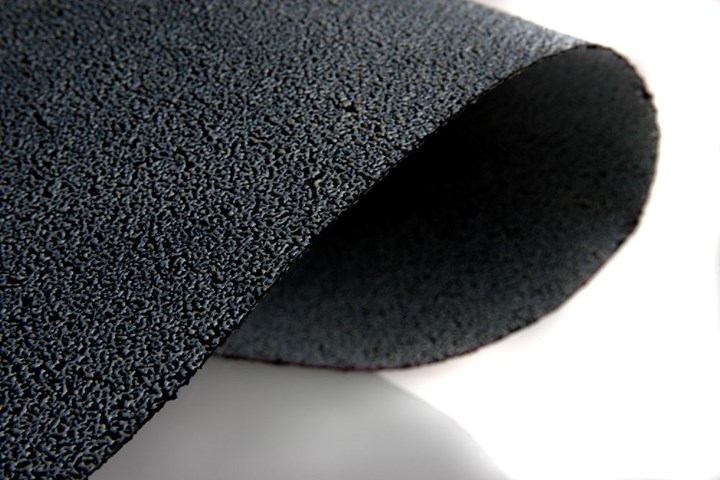

Teijin Tenax thermoplastic woven fabric (TPWF). Photo Credit: Teijin Teijin Ltd. (Tokyo, Japan) reported on April 12 that it has qualified its carbon fiber and polyetheretherketone (PEEK)-based materials Tenax thermoplastic woven fabric (TPWF) and Tenax thermoplastic consolidated laminate (TPCL) with NCAMP (National Center for Advanced Materials Performance, Wichita, Kan., U.S.). This is the first NCAMP qualification of a carbon fiber fabric-reinforced thermoplastic composite material. It is also the first NCAMP qualification of pre-consolidated laminates, which can be used for rapid thermoforming of stamped structural components. This qualification makes carbon fiber/PEEK fabric and consolidated laminate materials technology accessible to a much larger range of OEMs, Tier 1, and Tier 2 suppliers. Manufacturers can use the public NCAMP database to demonstrate equivalency and gain FAA certification at a lower cost than qualifying materials themselves. Teijin says this will be of interest to a variety of OEMs considering formed shapes with thermoplastic fabric and stamped forms like clips and brackets. Thermoplastic composites are also attractive to the growing advanced air mobility (AAM) market and traditional commercial aerospace sectors considering the benefits thermoplastics offer: high build rates, improved crack resistance, melt processing, increased opportunities for recycling, room temperature storage and multi-year shelf life. Tenax TPWF is a woven carbon fiber fabric coated with a thermoplastic polymer. Tenax TPCL are completely impregnated and consolidated sheets made of several layers of Tenax TPWF. The qualified product is based on woven Tenax high-strength carbon fiber and Vestakeep PEEK polymer from Evonik Industries AG (Marl, Germany), which achieves high heat, impact and fatigue resistance. Teijin says cost reduction with its qualified Tenax thermoplastic products is achieved through rapid molding processes that allow improved component manufacturing efficiency. This material is said to be suited for large-scale production of aerospace structural components with high performance requirements. In order to further support the introduction of this technology, Teijin created a material card of this specific material, which is used for process simulation using (Enschede, Netherlands) software. This is expected to help part makers and OEMs optimize the thermoforming process to quickly obtain the benefits of this type of material. |

Related Content

-

Welding is not bonding

Discussion of the issues in our understanding of thermoplastic composite welded structures and certification of the latest materials and welding technologies for future airframes.

-

Infinite Composites: Type V tanks for space, hydrogen, automotive and more

After a decade of proving its linerless, weight-saving composite tanks with NASA and more than 30 aerospace companies, this CryoSphere pioneer is scaling for growth in commercial space and sustainable transportation on Earth.

-

Carbon fiber, bionic design achieve peak performance in race-ready production vehicle

Porsche worked with Action Composites to design and manufacture an innovative carbon fiber safety cage option to lightweight one of its series race vehicles, built in a one-shot compression molding process.