National Composites Centre leads dismantlable joints research

Adhesive additive technology is reported to make composite parts easier to dismantle, maintain and recycle.

Source | National Composites Centre

The National Composites Centre (NCC, Bristol, U.K.) and Oxford Brookes University announce that they have developed a new technology that enables composite structures to be separated (or disbonded) quickly and cheaply using a simple heat source. With a goal of making it easy to work with, repair and disassemble composite parts, the researchers intend for this technology to significantly impact on the design, use and end-of life recycling of a wide range of products, including cars, aircraft and wind turbines.

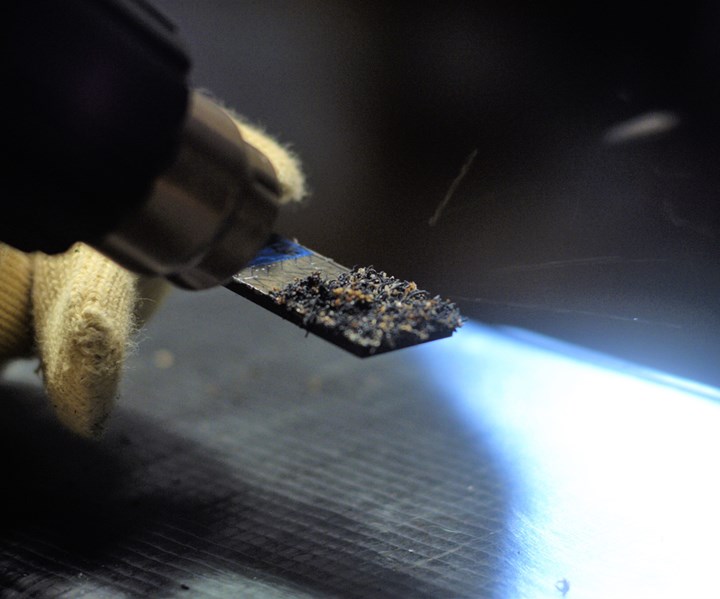

Researchers at Oxford Brookes University demonstrated that by adding low-cost additives to off-the-shelf structural adhesives, composite parts could be separated in as little time as six seconds by raising the temperature of the joint to approximately 160°C. The National Composites Centre reports that it has now proved that the new approach works at an industrial scale as part of its Technology Pull-Through Programme, which exists to transition new ideas from the lab to the marketplace.

“With this technology, we can take [end-of-life composite] structures apart to be repaired, reconfigured, or used in different ways.”

Small quantities of expandable graphite (widely used for fire protection) or thermal expandable microspheres are added to adhesives routinely used to bond composite parts. According to the NCC, these additives have minimal impact on the performance of components in normal operation, but when heated to the required temperature exert a force causing components to “pop apart.” This means, NCC says, that in the near future, composite components may be easily repositioned and reused during manufacturing – reducing waste, repaired in operation and recycled more efficiently at the end of their working life.

“This is a really exciting development, especially with sustainability being an increasingly significant challenge for the industry,” says Lucy Eggleston, research engineer at the NCC. “Historically, when a part is damaged or reaches the end of its life, it would be classed as waste and discarded. With this technology, we can take these structures apart to be repaired, reconfigured, or used in different ways. This could increase available end-of-life strategies for components, ultimately reducing their impact on the environment.”

For example, the automotive sector, NCC says, is looking to increase its use of composites and bonded parts in order to reduce vehicle weight. Vehicles also have to be 85% recyclable to comply with end-of-life directives. The new technology would reportedly enable mechanics to swap damaged parts using a simple heat gun. Recyclers could put whole cars through low-temperature ovens and watch them dissemble themselves in seconds.

The researchers also hope to extend this technology to recycling of the large amounts of carbon fiber and glass fiber composites on scrapped aircraft and wind turbine blades.

“We’ve been looking at ways to disbond structural adhesives for about 10 years, and working with the NCC through the Technology Pull-Through programme has enabled us to prove the technology readiness of our research,” says Professor James Broughton, head of the Joining Technology Research Centre at Oxford Brookes University. “We can now work with industry to fully optimize the technology for specific applications and tailor it for them as required.”

Related Content

Plant tour: Daher Shap’in TechCenter and composites production plant, Saint-Aignan-de-Grandlieu, France

Co-located R&D and production advance OOA thermosets, thermoplastics, welding, recycling and digital technologies for faster processing and certification of lighter, more sustainable composites.

Read MoreAirbus works to improve the life cycle of composites in future aircraft

This companion article to CW's September 2024 Airbus Illescas plant tour discusses recycling, LCA, biocomposites, Fast Track technologies, qualification and more.

Read MoreBladder-assisted compression molding derivative produces complex, autoclave-quality automotive parts

HP Composites’ AirPower technology enables high-rate CFRP roof production with 50% energy savings for the Maserati MC20.

Read MoreWatch: A practical view of sustainability in composites product development

Markus Beer of Forward Engineering addresses definitions of sustainability, how to approach sustainability goals, the role of life cycle analysis (LCA) and social, environmental and governmental driving forces. Watch his “CW Tech Days: Sustainability” presentation.

Read MoreRead Next

Ceramic matrix composites: Faster, cheaper, higher temperature

New players proliferate, increasing CMC materials and manufacturing capacity, novel processes and automation to meet demand for higher part volumes and performance.

Read MoreCutting 100 pounds, certification time for the X-59 nose cone

Swift Engineering used HyperX software to remove 100 pounds from 38-foot graphite/epoxy cored nose cone for X-59 supersonic aircraft.

Read MoreUltrasonic welding for in-space manufacturing of CFRTP

Agile Ultrasonics and NASA trial robotic-compatible carbon fiber-reinforced thermoplastic ultrasonic welding technology for space structures.

Read More.jpg;width=70;height=70;mode=crop)